Comprehensive Guide to Static Batching System Pricing and Maintenance

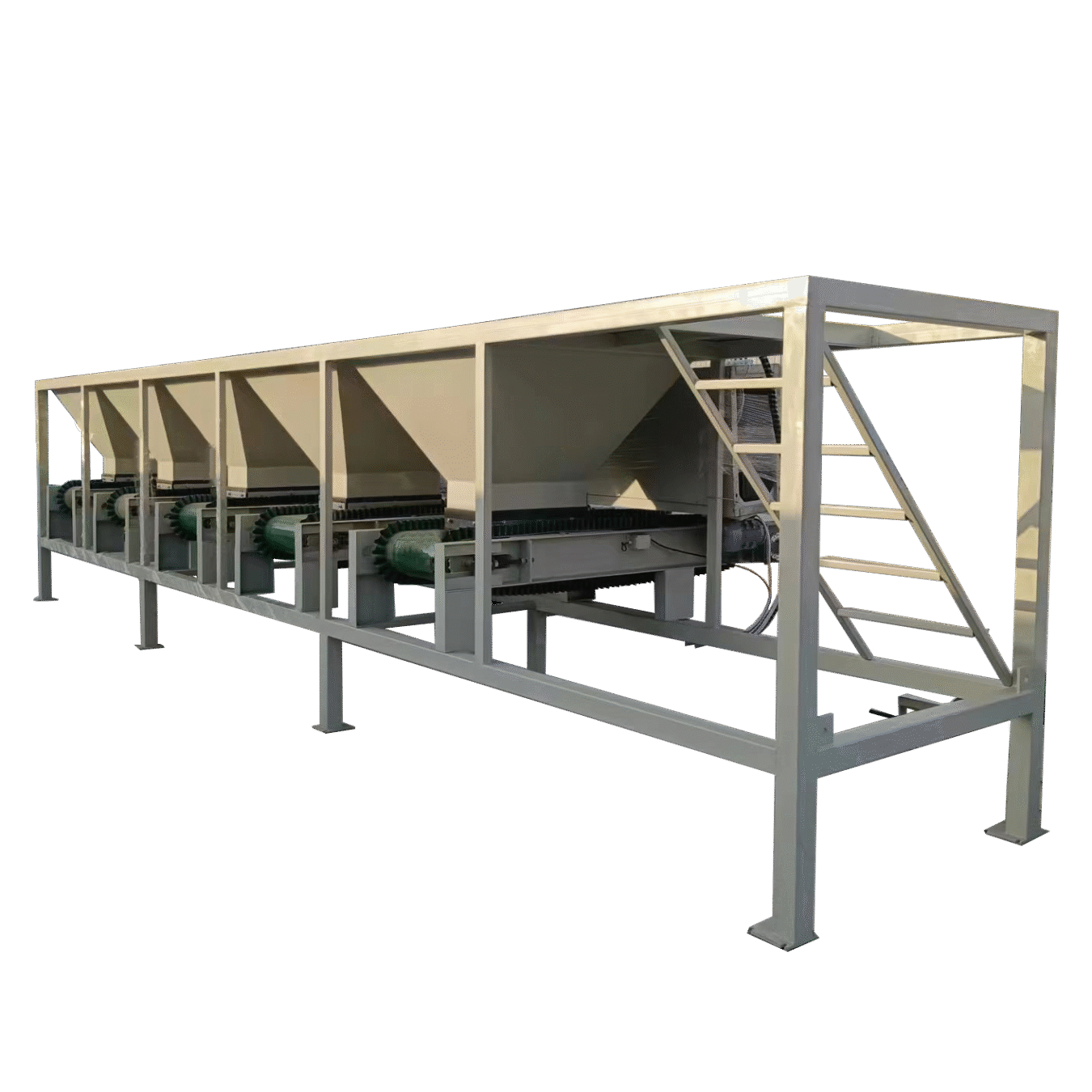

Static batching systems, known for their high precision and reliability, are a classic solution for batch production. Yuhang Technology Co., Ltd. offers an in-depth analysis of the pricing structure and daily maintenance requirements of static batching systems to help you select the most suitable equipment for your production needs.

Static Batching System Price Range

The price of a static batching system typically starts at ¥80,000 RMB (approx. $11,000 USD), with high-end customized systems reaching ¥500,000 RMB (approx. $70,000 USD) or more. Specific pricing depends on the following key factors:

Key Pricing Factors

- Weighing Capacity and Accuracy Grade

- Basic model (500kg capacity, ±0.1% accuracy): ¥80,000–150,000

- Standard model (1000kg capacity, ±0.05% accuracy): ¥150,000–250,000

- High-precision model (2000kg capacity, ±0.02% accuracy): ¥250,000–500,000

- Material Requirements

- Carbon steel material: Base price

- 304 stainless steel: 30–50% additional cost

- 316 stainless steel: 60–100% additional cost

- Automation Level

- Manual control system: ¥80,000–150,000

- Semi-automatic system: ¥150,000–250,000

- Fully automatic system: ¥250,000–500,000

- Number of Batching Stations

- Single hopper system: ¥80,000–120,000

- Dual hopper system: ¥120,000–180,000

- Multi-hopper system (4 or more): Starting from ¥200,000

Daily Maintenance Requirements and Difficulty Analysis

Maintenance for static batching systems is relatively straightforward and includes the following tasks:

Daily Maintenance Tasks

- Cleaning and upkeep

- Daily: Surface cleaning and feeding port clearance (5–10 minutes)

- Weekly: Internal hopper inspection and cleaning (20–30 minutes)

- Monthly: Sensor cleaning and maintenance (30–60 minutes)

- Calibration Work

- Before daily use: Zero-point calibration (automatically completed)

- Weekly: Range calibration (15–20 minutes)

- Monthly: Comprehensive accuracy verification (1–2 hours)

- Wear Parts Maintenance

- Seals: Replace every 12 months

- Load cells: Inspect and calibrate every 24–36 months

- Pneumatic components: Maintain every 18–24 months

Maintenance Difficulty Assessment

- Technical difficulty: Low. Most maintenance tasks can be performed by regular operators.

- Time commitment: Approximately 10–20 minutes daily, 2–3 hours monthly for in-depth maintenance.

- Maintenance cost: Annual maintenance expenses account for about 1–3% of the equipment’s value.

Practical Tips to Reduce Maintenance Costs

- Regular operator training: Standardize operational procedures to reduce human errors.

- Maintain maintenance records: Document equipment performance and maintenance history.

- Manage spare parts inventory: Keep a reasonable stock of commonly used wear parts.

- Implement preventive maintenance: Conduct regular inspections to identify and resolve potential issues early.

Advantages of Yuhang Static Batching Systems

Our static batching systems are designed with maintenance convenience in mind:

- Modular design: Key components are independently modularized for quick replacement.

- Smart diagnostics: Real-time monitoring of equipment status with early fault warnings.

- User-friendly design: Easy access to maintenance points reduces difficulty.

- Remote technical support: Timely remote fault diagnosis and maintenance guidance.

Request a Custom Quote and Solution

Contact Yuhang Technology engineers today for accurate equipment pricing and tailored maintenance solutions. We ensure you receive the most economical and reliable static batching system for your needs.

Leave a Comment

Your email address will not be published. Required fields are marked *