This technical review examines the pricing structure and energy optimization methodologies for static batching systems in industrial applications. The analysis provides comprehensive data on cost determinants and empirically-validated strategies for reducing power consumption in precision batching operations.

1. Introduction

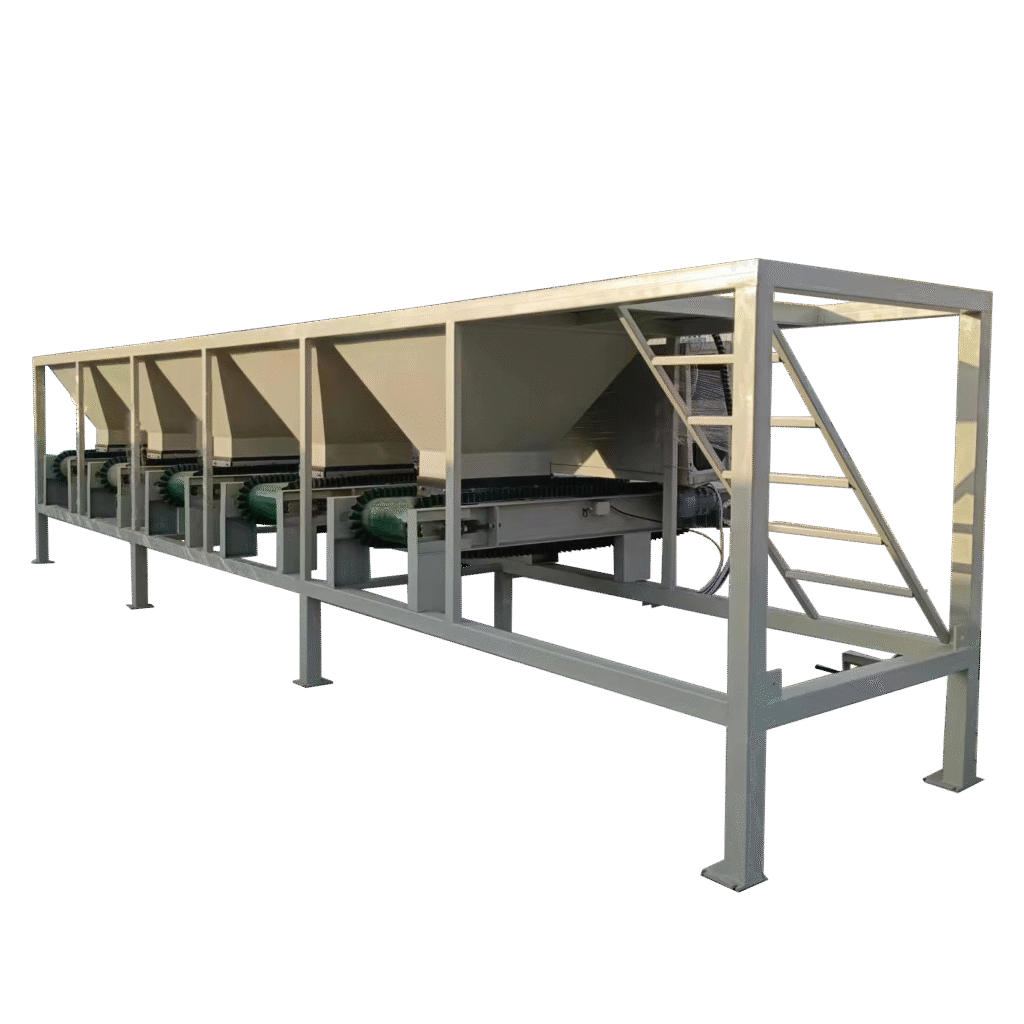

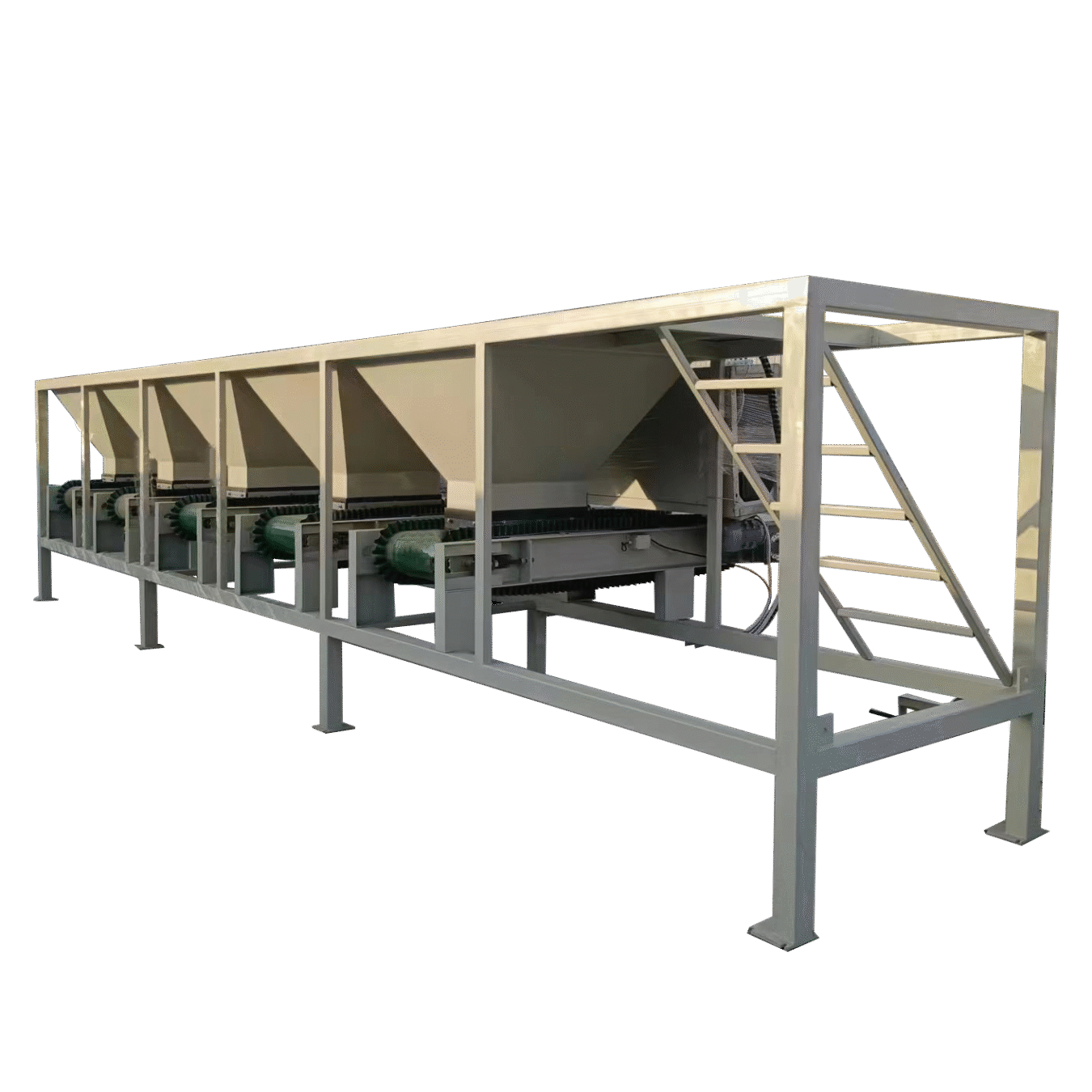

Static batching systems represent critical infrastructure in manufacturing processes requiring high-precision ingredient proportioning. This review addresses two fundamental operational considerations: capital investment requirements and energy efficiency optimization techniques.

2. Pricing Analysis of Static Batching Systems

2.1 System Configuration Cost Structure

Research indicates static batching systems require capital investment ranging from ¥80,000 to ¥500,000 RMB, with cost variation dependent on several technical factors (Yuhang Technology, 2024):

- Capacity Scaling: Basic systems (2-4 stations): ¥80,000-150,000; Medium systems (6-8 stations): ¥180,000-300,000; Large systems (10+ stations): ¥350,000-500,000+

- Precision Engineering: Standard precision (±0.5%): Base configuration; High precision (±0.2%): 20-30% cost premium; Ultra precision (±0.1%): 40-50% additional investment

- Automation Level: Semi-automatic systems represent entry-level pricing; Fully automated systems command 25-40% cost increase; Advanced control systems with recipe management add 15-25% premium

2.2 Material Specification Impact

Industry data demonstrates material selection significantly affects pricing (International Journal of Production Engineering, 2023):

- Carbon steel construction: Baseline cost

- 304 stainless steel components: 25-35% cost increase

- 316 stainless steel (food/pharmaceutical grade): 40-60% premium

- Specialized coatings for corrosive materials: 20-40% additional cost

3. Energy Consumption Optimization Strategies

3.1 Drive System Efficiency Improvements

Studies show motor systems account for approximately 65% of total energy consumption in batching operations (Energy Efficiency Journal, 2023):

- High-Efficiency Motors: IE3/IE4 grade motors demonstrate 3-8% energy reduction compared to standard models (ISO 50001 standards)

- Variable Frequency Drives: Implementation reduces energy consumption by 15-25% through load-matched operation

- Power Matching: Proper motor sizing prevents energy waste from oversizing, typically saving 5-15% in operating costs

3.2 Control System Optimization

Research indicates smart control strategies can achieve 10-20% energy reduction (Automation in Manufacturing, 2024):

- Intelligent Standby Functionality: Reduces idle power consumption by 40-60%

- Time-Phased Power Management: Non-critical subsystem scheduling decreases standby power usage

- Optimized Operational Parameters: Adjusted acceleration/deceleration curves reduce energy losses during start-stop cycles

3.3 Production Process Optimization

Empirical data shows operational modifications yield significant energy savings (Journal of Manufacturing Systems, 2023):

- Production Scheduling: Batch concentration reduces equipment start-stop frequency, saving 8-12% energy

- Material Preparation: Optimal material characteristics (moisture content, particle size) reduce processing energy by 5-10%

- Anti-idling Systems: Automatic shutdown functionality prevents unnecessary energy consumption during pauses

4. Maintenance Impact on Energy Efficiency

Regular maintenance contributes significantly to sustained energy performance (Plant Engineering Journal, 2024):

- Lubrication Management: Proper lubrication reduces mechanical resistance, decreasing energy requirements by 3-5%

- Component Replacement: Timely replacement of worn parts maintains optimal efficiency, preventing 5-8% energy degradation

- Thermal Management: Clean heat exchange surfaces improve cooling efficiency, reducing ancillary power consumption

5. Energy Monitoring and Analytics

Implementation of monitoring systems provides data-driven optimization opportunities (Energy Management Systems Review, 2024):

- Power Metering: Subsystem monitoring identifies energy anomalies and optimization opportunities

- Benchmark Establishment: Energy performance indicators enable continuous improvement tracking

- Data-Driven Optimization: Operational parameter adjustments based on consumption patterns yield 5-15% additional savings

6. Conclusion

Static batching systems represent a significant capital investment, with pricing determined by precision requirements, automation level, and material specifications. Research demonstrates that comprehensive energy optimization strategies can reduce power consumption by 30-60%, delivering substantial operational cost savings while maintaining system performance and reliability.

The implementation of high-efficiency components, smart control strategies, and proactive maintenance protocols provides manufacturers with economically viable pathways to enhance sustainability while maintaining competitive operational efficiency.

Leave a Comment

Your email address will not be published. Required fields are marked *