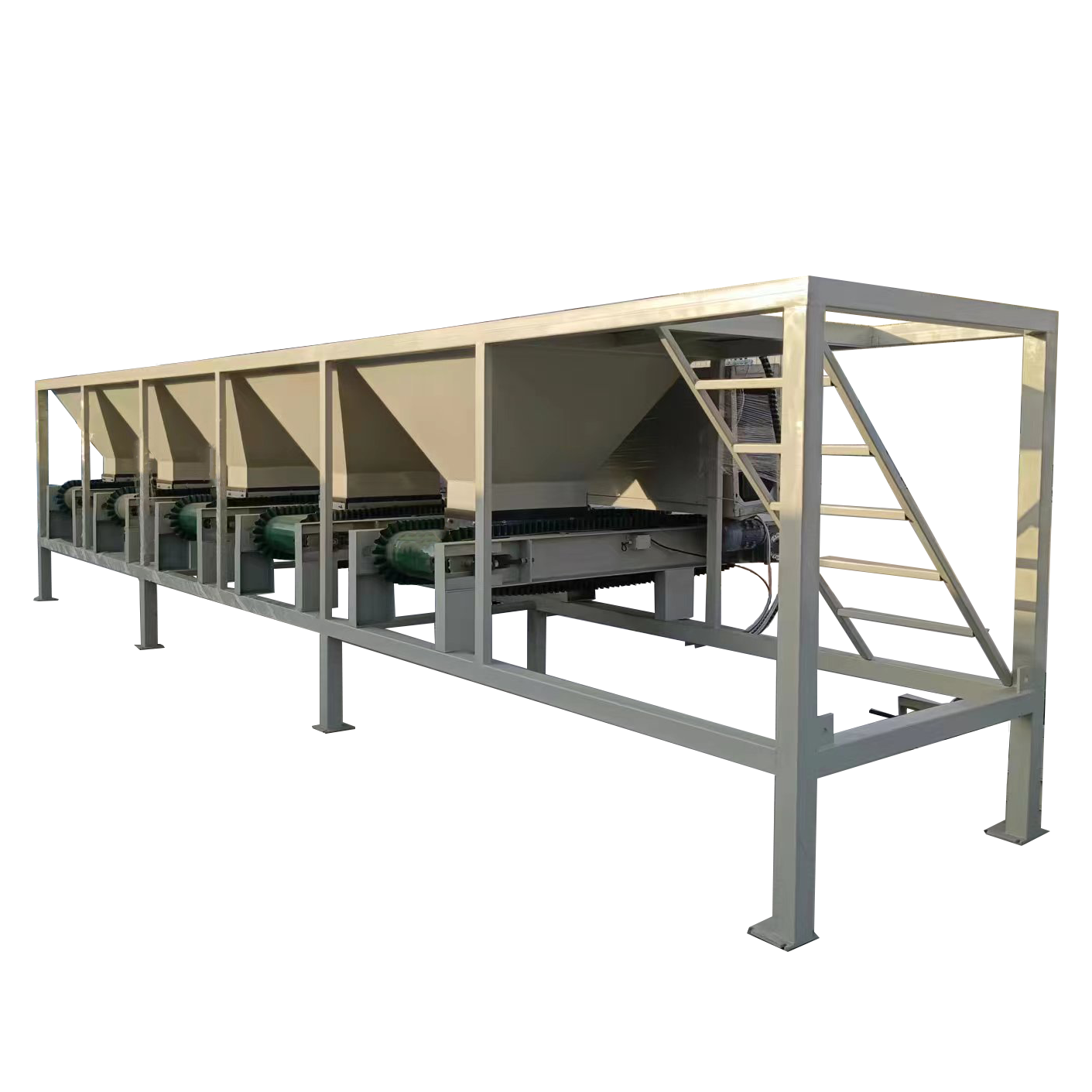

Dynamic Batching System: Comprehensive Pricing and Maintenance Guide

Dynamic batching systems are essential for continuous production processes, offering efficiency and automation. This guide provides detailed information on pricing and critical maintenance considerations to help you make an informed decision.

Dynamic Batching System Pricing

The price of a dynamic batching system typically ranges from ¥150,000 to over ¥1,000,000 RMB, depending on several key factors:

Primary Cost Factors

- System Capacity and Scale: Basic systems with 4-6 material stations start at approximately ¥150,000-300,000. Larger systems with 8-12 stations or more can range from ¥400,000-800,000. Customized, high-capacity solutions may exceed ¥1,000,000.

- Precision Requirements: Standard systems with ±1% accuracy represent the baseline price. High-precision systems achieving ±0.5% accuracy typically increase costs by 15-25%. Ultra-precision systems (±0.2%) may command a 30-50% premium.

- Automation Level: Semi-automatic systems serve as the entry point. Fully automated systems with advanced PLC controls and recipe management add 25-35% to the base cost. Systems with IoT connectivity and data analytics capabilities further increase investment by 15-20%.

- Material Handling Specifications: Standard carbon steel construction represents the baseline. Stainless steel (304 grade) components add 20-30% to the cost, while corrosion-resistant (316 grade) materials increase prices by 40-60%. Specialized coatings or treatments for abrasive or corrosive materials may add 25-50%.

- Additional Features: Integration with existing production lines, specialized safety systems, and custom software interfaces typically add 10-20% to the total system cost.

Essential Maintenance Considerations

Proper maintenance is crucial for ensuring optimal performance and longevity of dynamic batching systems. Here are key maintenance aspects to consider:

Regular Maintenance Requirements

Daily Maintenance Tasks:

- Visual inspection of all moving components and conveyor systems

- Verification of control system parameters and alarm functions

- Basic cleaning of exterior surfaces and inspection areas

- Check for material buildup or blockages in feeding mechanisms

Weekly Maintenance Procedures:

- Comprehensive inspection of weighing mechanisms and sensors

- Verification of calibration settings and accuracy checks

- Inspection of mechanical components for wear or misalignment

- Lubrication of moving parts as specified by the manufacturer

- Review of system performance data and error logs

Monthly Maintenance Activities:

- Full system calibration and accuracy verification

- Detailed inspection of electrical connections and components

- Thorough cleaning of internal components and material contact surfaces

- Preventive replacement of wear-prone components

- Software updates and backup of system parameters

Critical Maintenance Considerations

Calibration and Accuracy Maintenance:

Dynamic batching systems require regular calibration to maintain precision. Environmental factors, material characteristics, and mechanical wear can affect accuracy. Implement a strict calibration schedule and maintain detailed records of all adjustments.

Wear Part Management:

Identify critical wear components such as feeder screws, conveyor belts, bearings, and seals. Maintain an inventory of essential spare parts to minimize downtime. Track component lifespan and implement preventive replacement schedules.

Material-Specific Considerations:

Different materials present unique maintenance challenges. Abrasive materials accelerate wear on mechanical components. Hygroscopic materials may cause clogging or buildup. Corrosive materials require more frequent inspection of material contact surfaces.

Environmental Factors:

Temperature fluctuations, humidity, and dust levels can impact system performance. Implement appropriate environmental controls and protective measures. Regularly inspect seals, enclosures, and protection systems.

Software and Control System Maintenance:

Regularly back up system parameters and recipes. Keep control software updated with the latest versions. Monitor system logs for error patterns or performance degradation indicators.

Maintenance Cost Considerations

Annual maintenance costs typically range from 3-7% of the initial system investment. Factors affecting maintenance costs include:

- System complexity and automation level

- Operating hours and production intensity

- Material characteristics and abrasiveness

- Environmental conditions

- Quality of initial installation and commissioning

Yuhang Technology Support Services

Yuhang Technology provides comprehensive support for dynamic batching systems:

Maintenance Services:

- Scheduled preventive maintenance programs

- Emergency repair and technical support

- Remote diagnostics and troubleshooting

- On-site technical assistance

- Spare parts management and supply

Technical Support:

- Operator training programs

- Maintenance staff certification

- Technical documentation and manuals

- Software updates and upgrades

- Performance optimization services

Service Packages:

- Basic maintenance agreements

- Comprehensive service contracts

- 24/7 technical support options

- Performance guarantee packages

- Customized service solutions

Conclusion

Investing in a dynamic batching system requires careful consideration of both initial costs and long-term maintenance requirements. Proper maintenance planning is essential for maximizing system performance, ensuring accuracy, and minimizing operational downtime.

For detailed pricing information specific to your requirements or to discuss maintenance service options, please contact our technical team for a personalized consultation and quotation.

Leave a Comment

Your email address will not be published. Required fields are marked *