Complete Analysis of Dynamic Batching System Pricing and Maintenance

As crucial equipment for achieving continuous, automated production, the price and ongoing maintenance costs of dynamic batching systems are core concerns for enterprise investment decisions. With years of industry experience, Yuhang Technology Co., Ltd. provides a detailed analysis of dynamic batching system price ranges and daily maintenance requirements to help you make informed choices.

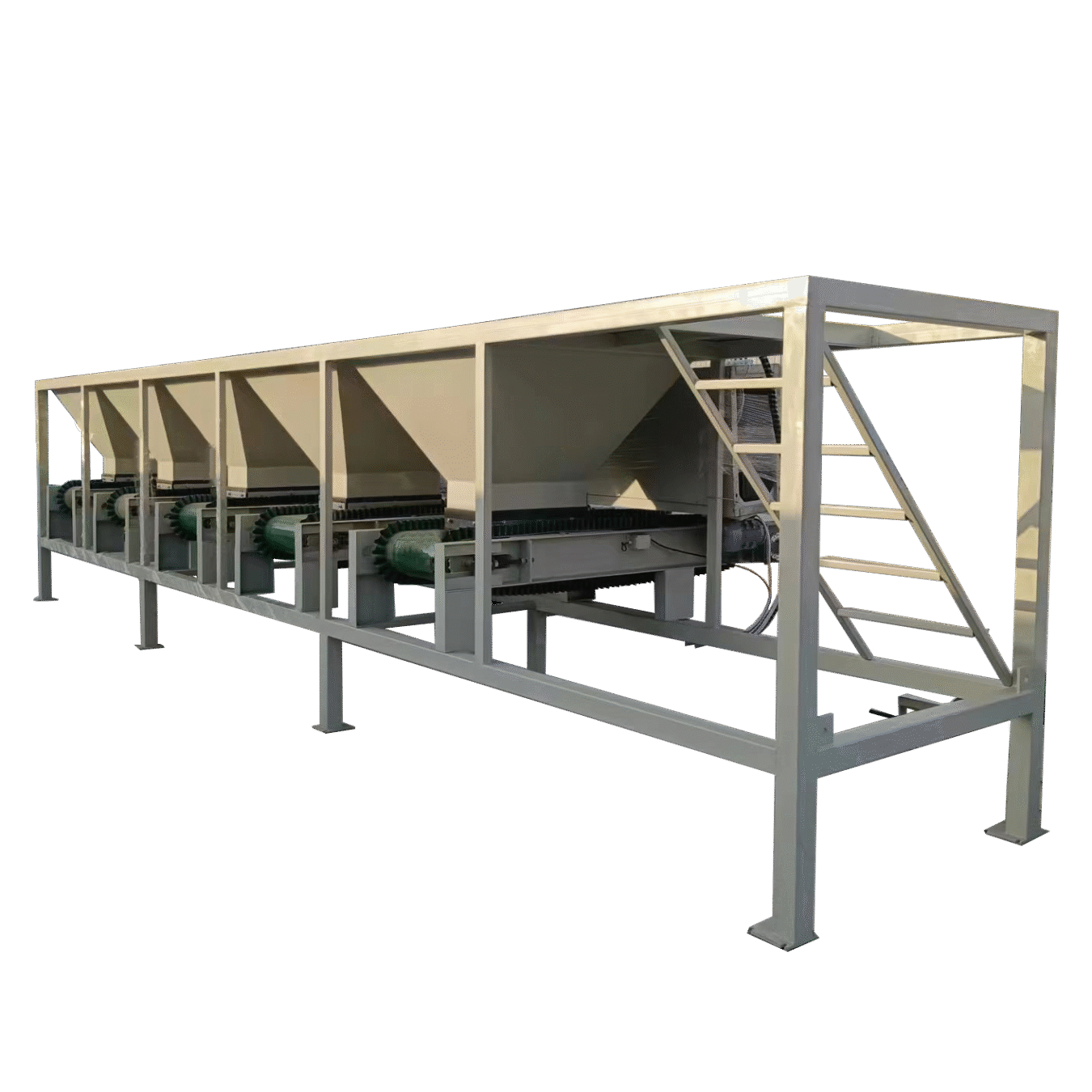

Dynamic Batching System Price Range

The price of dynamic batching systems is influenced by multiple factors, typically starting around ¥150,000 RMB ($20,000 USD), with large complex systems potentially exceeding ¥1,000,000 RMB ($140,000 USD). Specific pricing depends on the following key factors:

Main Factors Affecting Price

- System Scale & Number of Stations

- Basic system with 4-6 material stations: ¥150,000-300,000

- Medium system with 8-12 material stations: ¥300,000-600,000

- Large system with 12+ stations: ¥600,000-1,000,000+

- Accuracy Requirements

- Standard accuracy (±1%): Base price

- High accuracy (±0.5%): 15-25% additional cost

- Ultra-high accuracy (±0.1-0.2%): 30-50% additional cost

- Material Characteristics

- Standard materials: Standard configuration

- Special materials (adhesive, corrosive, flammable/explosive): Requires special materials and stainless steel design, adding 20-40% cost

- Automation Level

- Semi-automatic systems: Base price

- Fully automatic systems: 25-35% additional cost

- Smart systems (with data tracking, remote monitoring): 40-60% additional cost

Daily Maintenance Requirements & Difficulty

Daily maintenance of dynamic batching systems is not complicated but requires regular execution of the following tasks:

Daily Maintenance Content

- Cleaning Tasks

- Daily: External cleaning, feeding port cleaning (5-10 minutes)

- Weekly: Internal residue cleaning (30-60 minutes)

- Monthly: Thorough cleaning (1-2 hours)

- Calibration & Inspection

- Daily: Zero-point calibration (automatically completed)

- Weekly: Sensor inspection (15-20 minutes)

- Monthly: Comprehensive accuracy verification (1-2 hours)

- Wear Parts Replacement

- Seals: Replace every 6-12 months

- Conveying components: Replace every 12-24 months

- Sensors: Replace every 24-36 months

Maintenance Difficulty Assessment

- Technical Difficulty: Low to medium. Most daily maintenance can be performed by trained operators

- Time Commitment: Approximately 15-30 minutes daily, 2-4 hours monthly for deep maintenance

- Cost Investment: Annual maintenance costs typically account for 2-5% of system value

Practical Suggestions to Reduce Maintenance Costs

- Choose modular design: Enables quick replacement and repair, reducing downtime

- Equip with smart diagnostic systems: Early fault warnings prevent unexpected停机

- Regular operator training: Proper use reduces human-caused failures

- Establish preventive maintenance plans: Scheduled maintenance costs 60% less than emergency repairs

Why Choose Yuhang Dynamic Batching Systems?

Yuhang Technology’s dynamic batching systems are designed with maintenance convenience in mind:

- Modular design: Most components can be quickly disassembled and replaced

- Smart self-diagnosis: System automatically monitors operation status and prompts maintenance needs

- Remote support: Technical team can provide remote diagnosis and maintenance guidance

- Adequate spare parts supply: Ensures quick access to original parts

Get Custom Quote & Maintenance Plan

Every enterprise has unique needs. Contact Yuhang Technology engineers for accurate system pricing and customized maintenance solutions to ensure you invest in the most cost-effective dynamic batching solution.

Leave a Comment

Your email address will not be published. Required fields are marked *