Dynamic Batching System: Price and Comparison with Static Systems

Understanding the key differences between dynamic and static batching systems is crucial for selecting the right technology for your production line. Yuhang Technology provides a clear analysis of dynamic system pricing and a direct comparison of both technologies.

Dynamic Batching System Price Range

The investment for a dynamic (continuous) batching system is generally higher than for a static (batch) system. Pricing typically starts around ¥150,000 RMB and can exceed ¥1,000,000 RMB for large, complex, fully automated lines.

Several core factors influence the final cost:

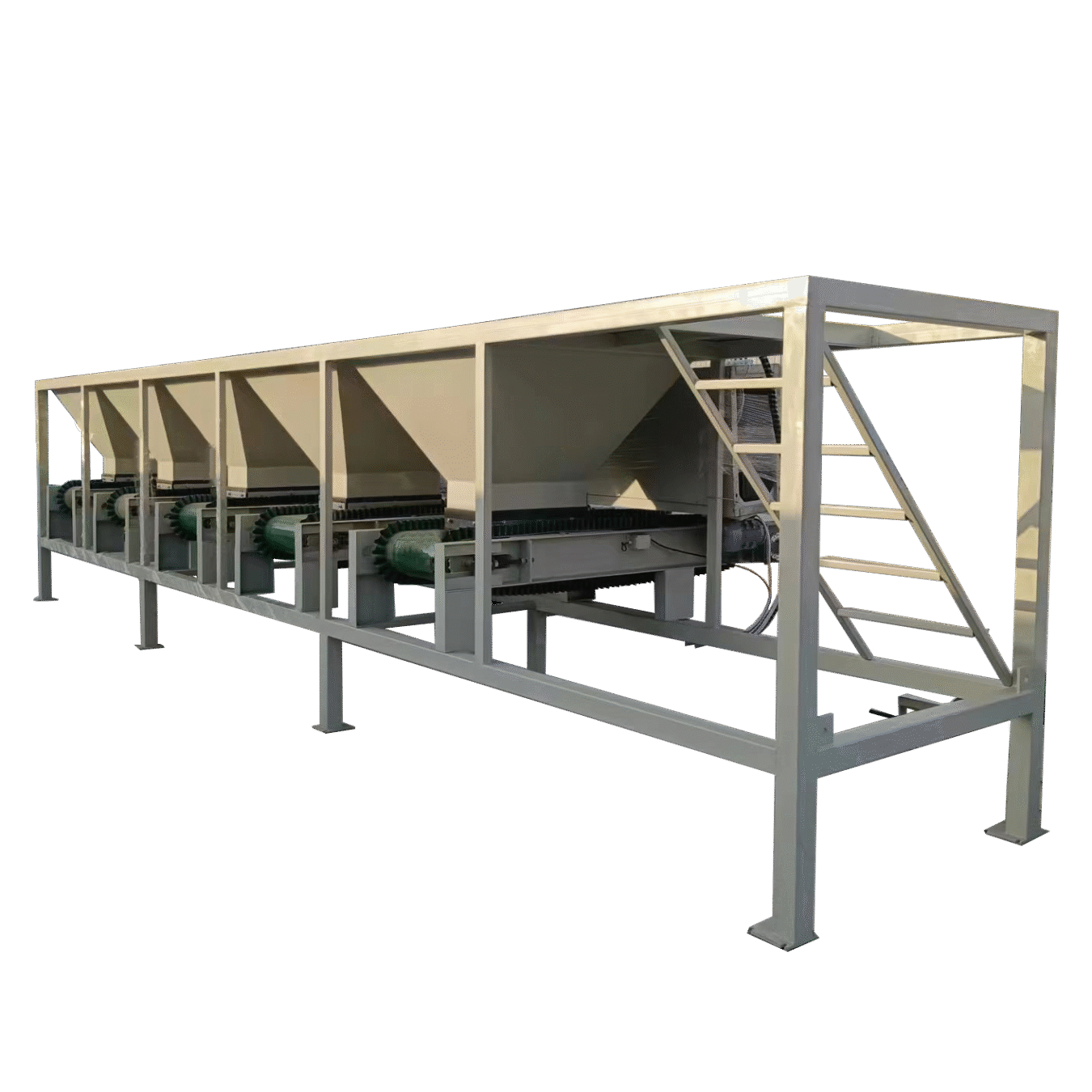

- System Scale: A basic system with 4-6 material stations typically ranges from ¥150,000 to ¥300,000.

- Accuracy Requirements: Standard precision (±1%) is the baseline. High-precision systems (±0.5%) can increase the cost by 15-25%.

- Automation Level: A semi-automatic system serves as the baseline price point. Upgrading to a fully automatic system adds 25-35% to the cost.

- Material Characteristics: Handling specialized materials (e.g., sticky, corrosive, or highly abrasive) requires custom engineering and can increase the price by 20-40%.

Dynamic vs. Static Batching Systems: Advantages and Disadvantages

Dynamic Batching System Advantages

- High Production Efficiency: Designed for continuous operation, they offer significantly higher output and are ideal for large-scale, high-volume production runs without stopping between batches.

- Excellent Flexibility: Recipe changes can often be made on-the-fly through the control system, making them perfect for production lines that require frequent product variety changes.

- Process Integration: They integrate seamlessly into a continuous production process, reducing material handling and streamlining the overall workflow from raw material to finished product.

- Consistent Output: Provides a steady, uninterrupted flow of mixed product, which is essential for downstream continuous processes.

Dynamic Batching System Disadvantages

- Higher Initial Investment: The technology, conveying systems, and controls are more complex, leading to a higher purchase price compared to static systems.

- Generally Lower Precision: While sufficient for most applications, achieving the ultra-high precision of a static weigh hopper is more challenging in a continuous flow environment. Accuracy is typically in the ±0.5% to ±1% range.

- More Complex Maintenance: The inclusion of continuous feeders, conveyors, and advanced control systems requires more sophisticated maintenance knowledge and can lead to higher long-term upkeep costs.

- Larger Footprint: The equipment for continuous feeding and mixing often requires more factory floor space.

Static Batching System Advantages

- Superior Accuracy: This is their primary strength. By weighing each ingredient individually in a dedicated hopper before discharge, they achieve the highest possible precision, often at ±0.1% or better.

- Lower Initial Cost: The simpler mechanical design and control requirements make them a more budget-friendly capital investment.

- Easier Maintenance: With fewer moving parts and a simpler operational concept, maintenance is generally more straightforward and can often be performed by in-house personnel.

- Compact Design: The batch-based nature allows for a more vertical and compact equipment layout, saving valuable floor space.

Static Batching System Disadvantages

- Lower Overall Output: Production occurs in distinct batches, meaning there is downtime between cycles for weighing, discharging, and cleaning, limiting maximum throughput.

- Reduced Flexibility: Changing recipes often requires purging the system or cleaning hoppers to prevent cross-contamination, which takes time and interrupts production.

- Not Suitable for Continuous Processes: The batch-discharge nature means they cannot directly feed a truly continuous downstream process without additional buffer equipment.

Summary and Selection Guidance

Choose a Dynamic Batching System if your priority is high-volume, continuous output, operational flexibility for frequent recipe changes, and integration into a full continuous processing line. It is the preferred choice for large-scale production in industries like plastics, compounded animal feed, and certain food production.

Choose a Static Batching System if your top priorities are utmost precision, a lower initial investment, simpler maintenance, and you operate with smaller batches or where product changeover is less frequent. It is ideal for applications in pharmaceuticals, specialty chemicals, high-end baking, and any process where recipe accuracy is critical.

Why Partner with Yuhang Technology?

At Yuhang Tech, we don’t just sell equipment; we provide solutions. Our experts will analyze your specific materials, production goals, and facility constraints to recommend the optimal system—dynamic or static.

We ensure:

- Customized Design tailored to your material characteristics and capacity needs.

- Precision Guarantee, whether for high-speed dynamic or high-accuracy static batching.

- Intelligent Control with advanced PLC and SCADA systems for seamless operation.

- Comprehensive Support from installation and training to ongoing maintenance.

Get Expert Guidance

Unsure which technology best fits your operation? Contact a Yuhang Technology engineer today for a free consultation, detailed system proposal, and a precise quotation tailored to your needs.

Leave a Comment

Your email address will not be published. Required fields are marked *