1. Core Characteristics and Advantages/Disadvantages of Static Blending System

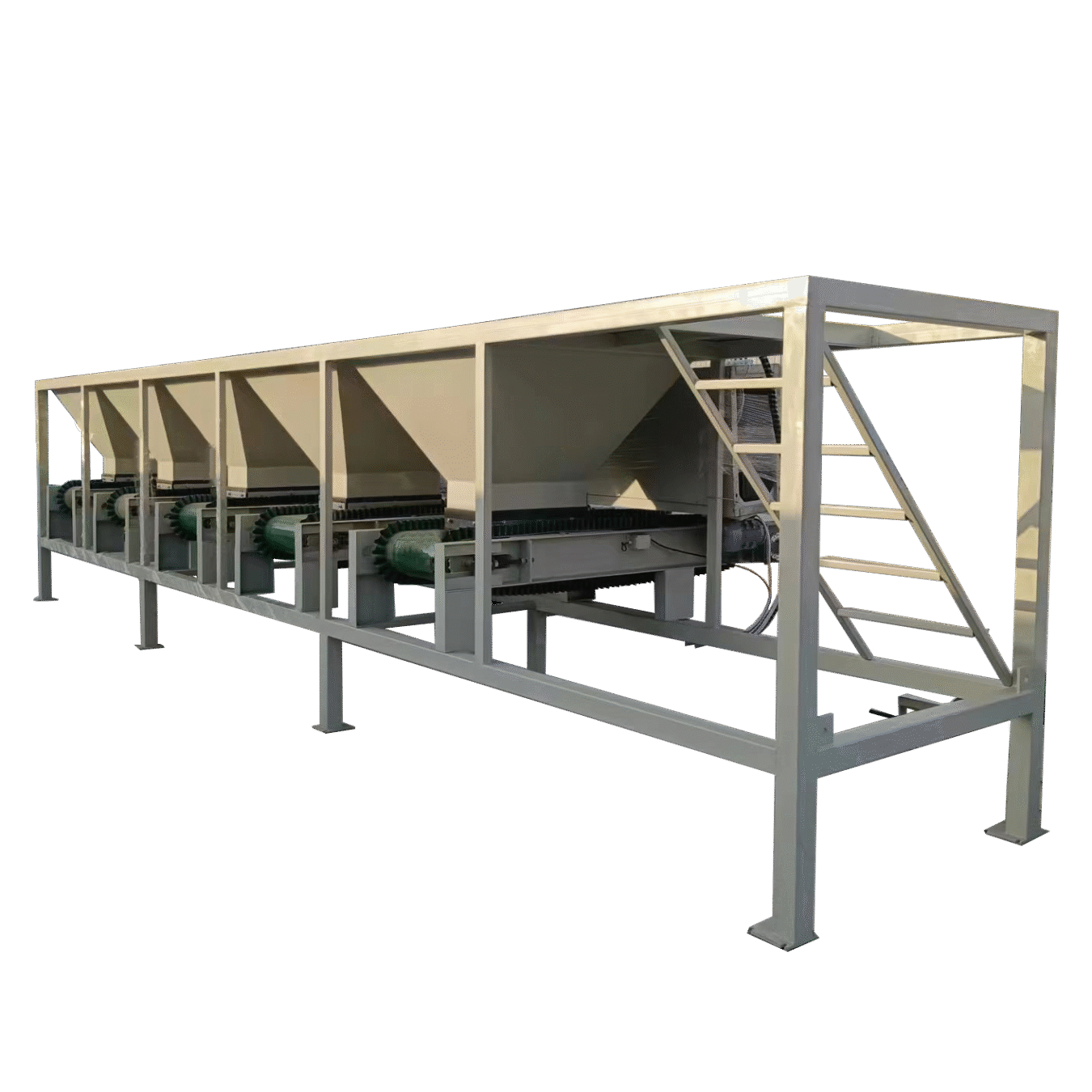

Essential Working Principle

The static blending system operates in a sequential feeding and centralized weighing mode. All materials are added to the same weighing hopper in the order specified by the formula. The precise weighing of each individual material is completed in a stationary state, and the complete batch is then discharged centrally.

Significant Advantages

- Single-point High Precision Guarantee

- Each type of material is independently weighed in a static state, eliminating dynamic interference

- For powdery materials with good fluidity (such as flour, cement), a weighing accuracy of ±0.1% can be achieved

- Typical application case: The ratio of main materials (cement, sand, and gravel) in dry-mixed concrete

- Structural Economy

- The single bucket design reduces mechanical complexity

- The equipment cost is only 60%-70% of that of dynamic systems

- The maintenance technical requirements are low, and the cost of spare parts replacement is controllable

- Sealed Anti-Pollution

- The fully sealed hopper structure complies with GMP certification requirements

- Food-grade stainless steel material supports CIP cleaning

- Applications in the pharmaceutical industry: Additives for tablet production

Technical Limitations

- Sequence Bottleneck Effect

- N types of materials require N independent feeding cycles

- The efficiency of 20 sets of formulations is over 40% lower than that of the dynamic system

- Example: The average daily batch production of feed premixes is ≤ 30 times

- Minor Component Distortion

- Adding grams of materials to the kilogram-sized main material hopper

- The relative error can reach ±5% when the addition amount is 0.1%

- Industry pain point: The accuracy of vitamins in premixes is out of control

- Material Residue Problem

- Residual amount of viscous materials (such as syrup) reaches 0.3 – 0.8%

- Risk of cross-contamination between batches

– Cleaning time accounts for 15% – 20% of the production cycle

2. Technical Characteristics and Capacity Limits of Dynamic Ingredient Dispensing System

Innovative Working Principle

Based on the Loss-in-Weight principle, each material is equipped with an independent weighing hopper. The feeding machine’s speed is dynamically adjusted by monitoring the rate of weight loss in real time, enabling the simultaneous and continuous output of multiple materials.

Technical Advancedness

- Continuous Flow Production Paradigm

- Parallel output of multiple components eliminates waiting time

- Capacity density increased by 35-50% (e.g. plastic granulation line)

- Supports 7×24-hour uninterrupted production

- Micro-scale Control Capability

- Special micro-scale weighing buckets (with a capacity of 0.5 – 5 liters)

- Even with an addition of 0.01%, the accuracy remains within ±0.3%

- Industry breakthrough: Addition of CNT conductive agent for lithium battery electrodes

- Adaptive Control System

- Dynamic compensation of density fluctuations using PID algorithm

- Automatic tuning to adapt to changes in material flow properties

- Case study: Seasonal variations in moisture content of raw materials in the food industry

Application Challenges

- Significant Increase in System Complexity

- The multi-bucket structure increases the number of failure points by 132%

- Professional control system engineers are required

- Typical maintenance cost: ¥8 – ¥12 thousand per year per system

- Feed Cycle Disturbance

- Volume mode switching leads to accuracy drift (±1.5%)

- Effective operation rate drops to ≤85% during high-frequency formula switching

- Solution: Dual-bucket alternate feeding system

- Spatial Economic Imbalance

- Each additional material requires 0.8 – 1.2 square meters of floor space.

- A 50-component system requires an installation area of over 60 square meters.

– Comparison: A static system with the same production capacity only requires 20 square meters.

III. System Selection Decision Matrix

Industry Adaptation Map

- Domain Dominated by Static Systems

- Building Mortar (fixed ratio of cement/sand and stone)

- Basic Feed (main ingredients of corn and soybean meal mixture)

- Standard Plastic Masterbatch (3-5 components)

- Dynamic System Essential Application Scenarios

- Active ingredient addition for pharmaceutical APIs (0.01 – 0.1%)

- High-end color masterbatch (synchronous ratio of 20+ pigments)

– New energy materials (continuous feeding of 6-component electrode slurry)

IV. Technological Integration Trends

Hybrid Architecture Innovation

- Hybrid System of Main Component and Micro Component

- The main component uses static weighing (accuracy ± 0.2%)

- The micro components implement dynamic weight loss control (accuracy ± 0.05%)

- Example: Production line for adding attractants to pet food

- Intelligent Compensation Algorithm

- Utilizes machine learning to predict the drift in the accuracy of feeding cycle

- Implements digital twin technology for pre-adjustment of control parameters

- Implementation effect: The effective operation rate has been increased to 93%

Breakthroughs in Materials Engineering - Nano-coating technology reduces residual in hoppers (<0.01%)

- Piezoelectric ceramic weighing sensors enhance dynamic response speed

– Air suspension feeders solve bridging issues for ultrafine powders (d50 < 10μm)

Conclusion and Recommendations

The static batching system still offers economic advantages in simple formulations and scenarios with moderate precision. However, the dynamic batching system has become the standard technology for complex formulations, continuous production, and precise micro-additions. In the next five years, hybrid architecture systems will cover 60% of new production lines. It is recommended that enterprises select precise technologies based on the material characteristic map (three-dimensional matrix of component quantity – micro proportion – rheological properties) and reserve 15% of intelligent upgrade space during new project construction.

Leave a Comment

Your email address will not be published. Required fields are marked *