Ingredient Mixing System: The Core Technology of Precise Mixing

In modern industrial production, whether in the fields of food, chemical engineering, pharmaceuticals, building materials or plastics, precise raw material ratios are the lifeline of product quality. The batching system, as the key equipment to achieve this goal, comes in various types and each has its own unique features. The following introduces several main types of batching systems and their characteristics:

**I. Classification by Working Principle and Structure: **

- Static Batch Blending System:

- Principle: According to the preset recipe sequence, various materials are weighed and sequentially added to the same central weighing drum (static hopper). After all the materials are added, the mixed batch is then discharged all at once.

- Features: The structure is relatively simple, with high precision (especially suitable for materials with good流动性 and not prone to sticking together), and the cost is moderate. It is suitable for scenarios where the recipe is fixed, batch production is carried out, and the number of material types is not particularly large (such as ten or twenty types). However, the blending cycle is relatively long (waiting for each type of material to be added sequentially).

- Dynamic Batch Blending System (Weightless Blending System):

- Principle: Each material has an independent weighing hopper (weightless hopper). During blending, the system continuously monitors the weight loss rate of each hopper (i.e., the rate at which the material flows out), and uses high-precision sensors and fast-response controllers to adjust the feeding equipment (such as screws, vibrating feeders) in real time, ensuring that various materials flow out simultaneously and in precise proportions, entering downstream mixers or conveyor lines.

- Features: Fast blending speed (continuous or quasi-continuous feeding), extremely high precision (especially suitable for trace components or scenarios with strict proportion requirements), high level of automation, suitable for multi-component (several dozen types) and frequently changing formulas in continuous or batch production. However, the system is complex, has a relatively high cost, and requires high standards for feeding equipment and control algorithms.

- Continuous Blending System:

- Principle: Materials are continuously transported to a single conveying line through their respective feeding devices (such as belt scales, nuclear scales, impact plate flow meters, screw scales, etc.), in accordance with the set ratios, to achieve continuous mixing of the materials.

- Features: It truly realizes uninterrupted continuous production, suitable for large-scale, single-formulation or processes with few formulation changes in industrial sectors (such as cement, feed, large-scale chemicals). The system has a large processing capacity. The accuracy is usually lower than batch-based (especially dynamic batch), and it has a high dependence on the material properties and the stability of the flow meters.

**II. Classification by Precision Level and Application: **

- Macro Ingredient System:

- Application: Primarily used for the ratio of main raw materials or for additives with a large amount. The requirement for absolute precision is relatively loose (usually within ±0.5% – ±1%), but it requires stability and processing capacity.

- Typical Equipment: Belt scales, plate flow meters, large spiral scales, main material large hoppers in static batch systems. Commonly used in the batching of building materials, feed, and basic chemical raw materials.

- Microscale/Microportioning System:

- Application: Used for adding extremely small quantities (possibly as low as ppm level) but with significant impact on product performance, such as additives, catalysts, vitamins, flavors, pigments, etc.

- Typical Equipment: High-precision weight-loss feeders (single/double screw, vibrating type), liquid micro-pumps, micro-scale balances in static batch systems (using high-resolution sensors and precise feeding mechanisms). The precision requirements are extremely high (often needing ±0.1% – ±0.5% or even higher), which is the core difficulty of the system.

**III. Classification by Material Form: **

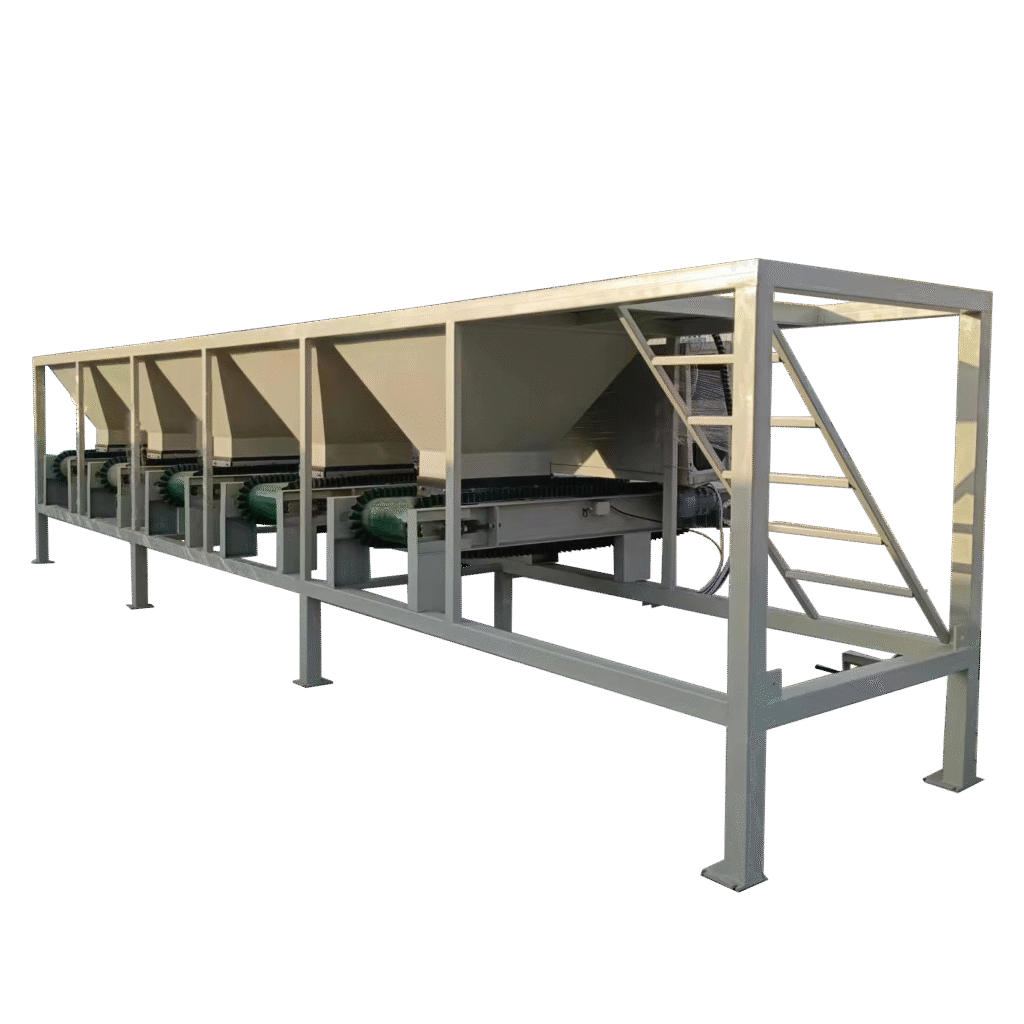

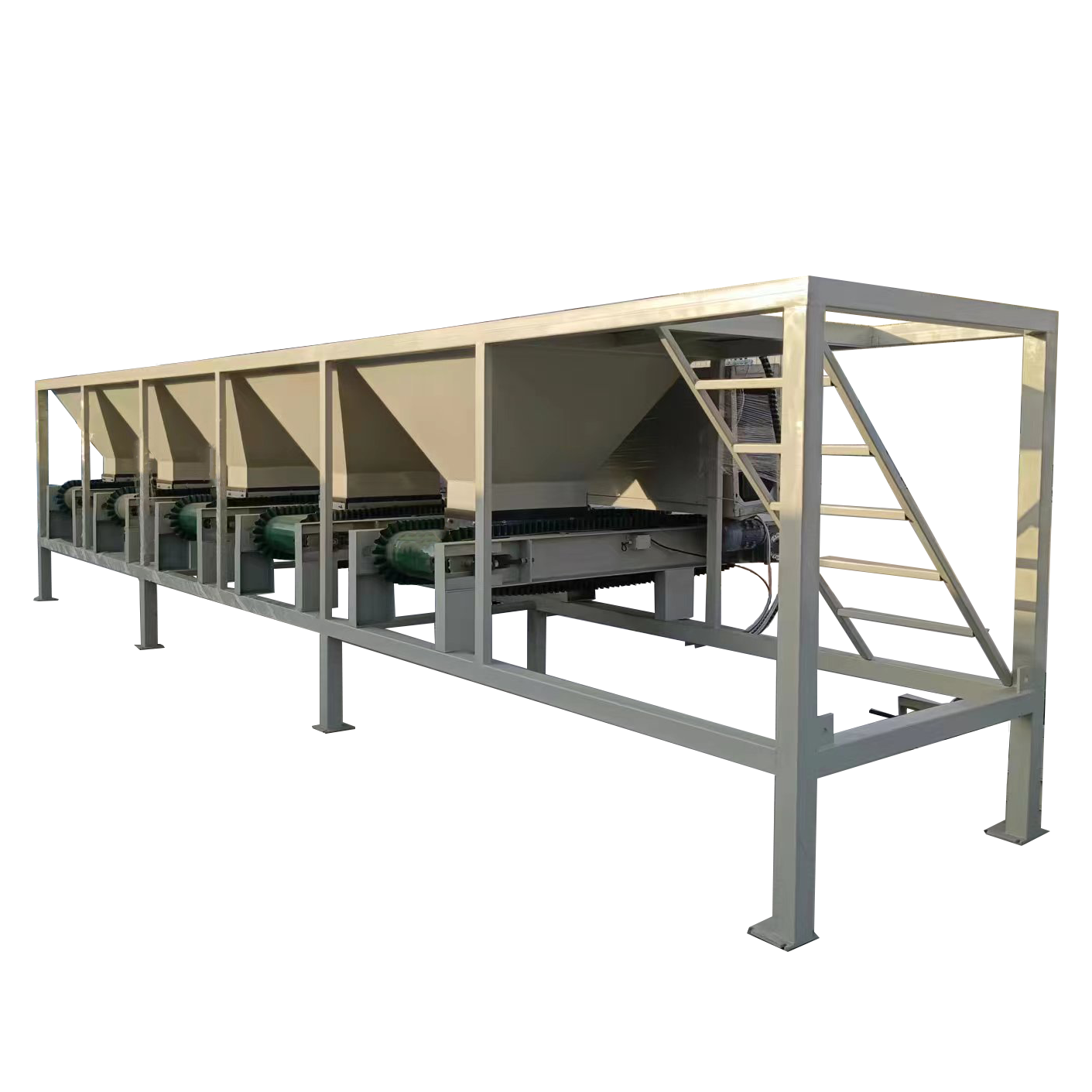

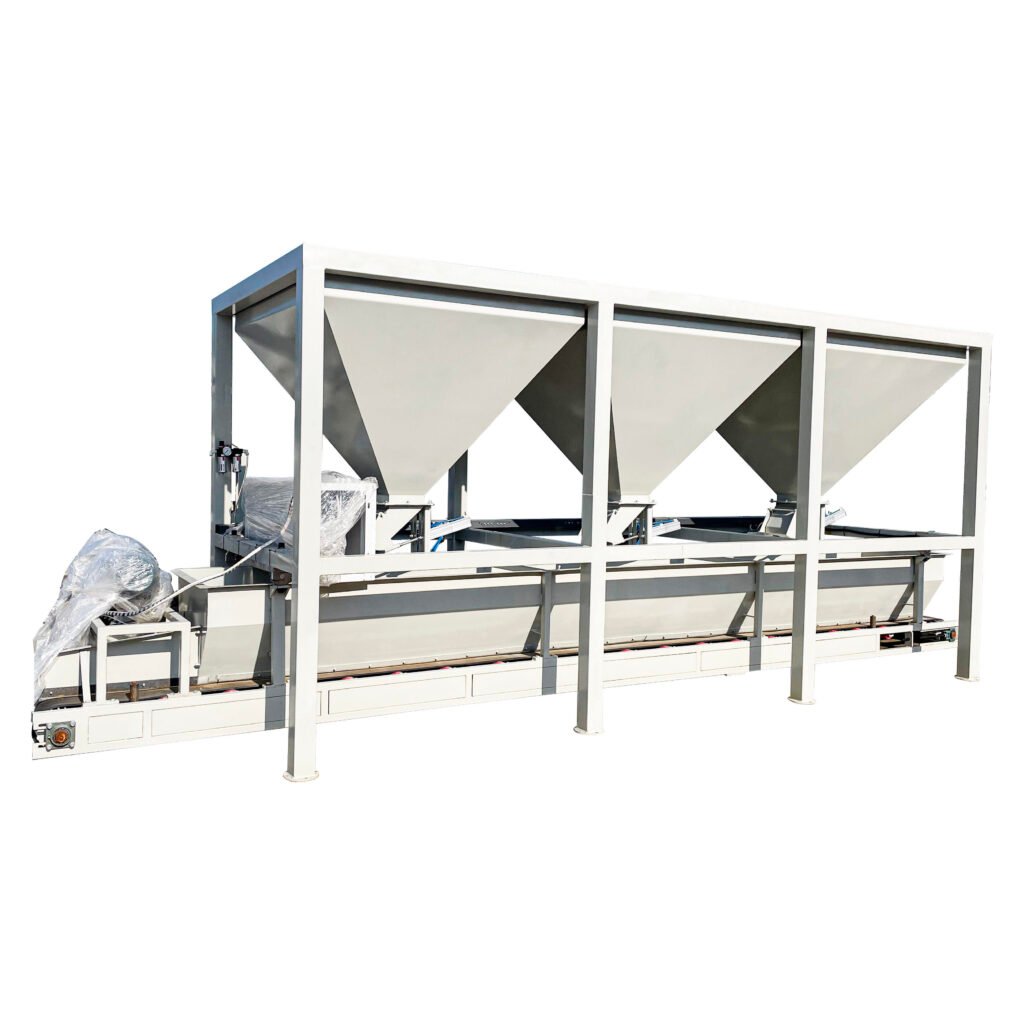

- Powder and Granule Material Mixing System: The most common type, involving various dry bulk materials such as powders, particles, and crystals. It needs to address issues such as fluidity, bridging, dust generation, and adhesion. Common equipment includes screw feeders, vibrating feeders, rotary valves, pneumatic conveying combined with weighing, etc.

- Liquid Mixing System: Involves water, oil, solvents, liquid additives, etc. The core is precise volume or mass flow measurement and control. Common equipment includes flow meters (mass/volume), metering pumps, weighing tanks, etc. Consider factors such as viscosity, temperature, and foam.

- Pulp/Gel-like Material Mixing System: Intermediate between solids and liquids, with poor fluidity and high measurement difficulty. Common equipment includes screw pumps, plunger pumps, specially designed weightless hoppers or static weighing hoppers with stirring.

Key factors for selecting the配料 system

- Material Characteristics: Form (powder/granule/liquid/cream), fluidity, density, hygroscopicity, viscosity, corrosiveness, explosiveness, etc.

- Formulation Requirements: Component quantities, range of proportions for each component (especially trace components), precision requirements (tolerance), frequency of formulation changes.

- Production Process: Batch or continuous? Production scale (hourly/batch processing capacity)? Degree of automation required? Connection with upstream and downstream equipment (such as mixers, conveying lines, packaging machines).

- Environment and Regulations: Hygiene level (such as GMP requirements for food and medicine), explosion prevention requirements, environmental protection requirements (dust, odor control).

- Investment and Maintenance Costs: System complexity, equipment purchase cost, installation and commissioning cost, long-term maintenance cost.

Summary:

The batching system is an indispensable part of modern industrial automated production. From static batches to dynamic weight loss, and then to continuous batching; from macro bulk materials to micro precise additions; from powder and granular materials to liquid slurries, the diverse system types meet the precise ratio requirements of different industries, different processes, and different materials. Choosing the appropriate batching system requires comprehensive consideration of factors such as material characteristics, process requirements, precision targets, and cost budgets, in order to achieve efficient, stable, and precise production goals. With the development of sensor technology, control algorithms, and the industrial Internet of Things, the batching system is constantly evolving towards higher precision, higher efficiency, greater intelligence, and easier integration.