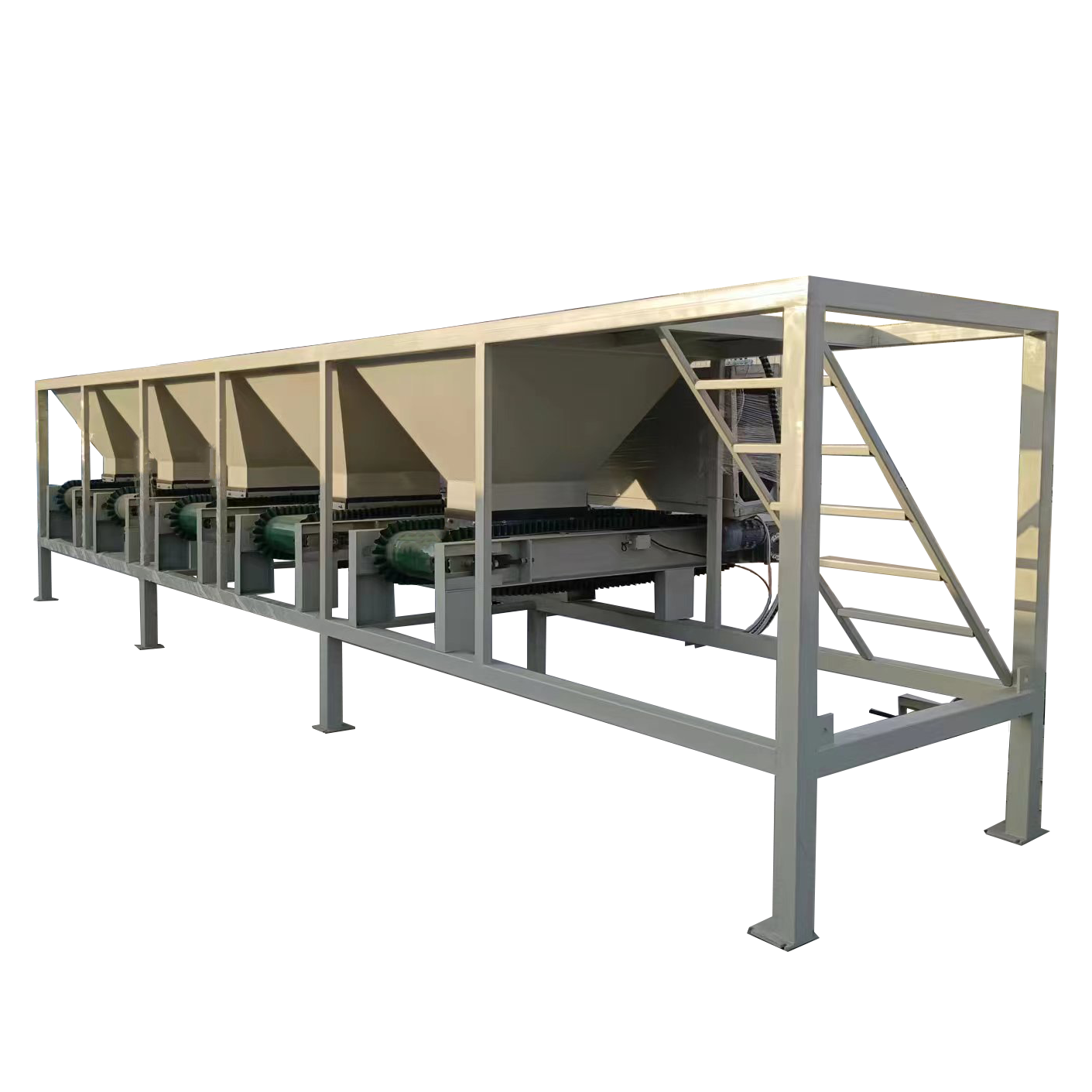

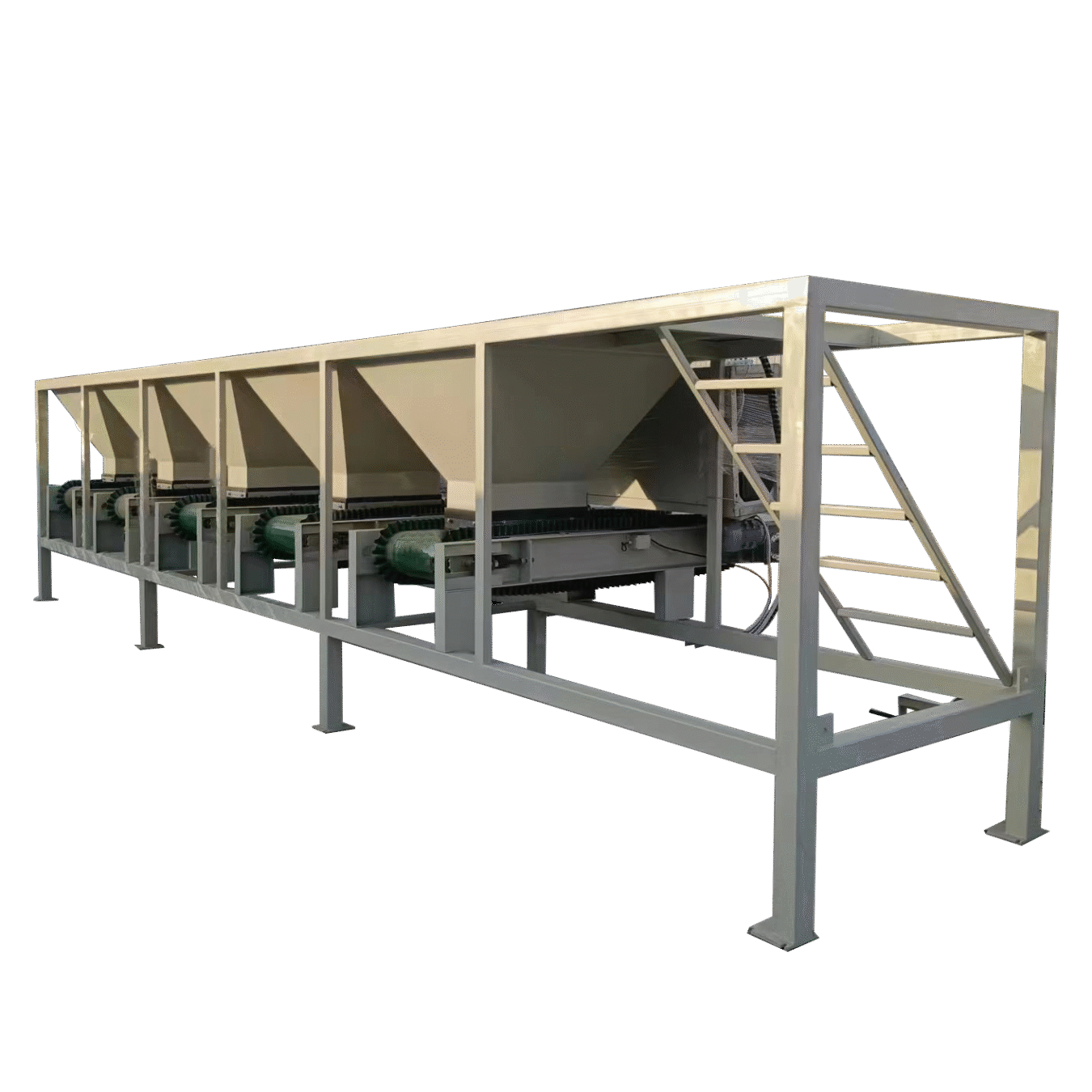

Dynamic Batching System: Pricing Overview and Energy Efficiency Solutions

Dynamic batching systems are vital for continuous production processes, offering high efficiency and automation. This guide provides detailed pricing information and effective strategies to minimize power consumption.

Dynamic Batching System Pricing

The investment for a dynamic batching system typically ranges from ¥150,000 to over ¥1,000,000 RMB, depending on several key factors:

Primary Cost Factors

- System Capacity: Basic systems (4-6 material stations) start at ¥150,000-300,000. Medium-scale systems (8-12 stations) range from ¥400,000-800,000. Large, customized systems may exceed ¥1,000,000.

- Precision Requirements: Standard systems (±1% accuracy) represent baseline pricing. High-precision systems (±0.5%) increase costs by 15-25%, while ultra-precision systems (±0.2%) may command a 30-50% premium.

- Automation Level: Semi-automatic systems serve as entry-level options. Fully automated systems with advanced controls add 25-35% to the base cost. IoT connectivity and data analytics capabilities further increase investment by 15-20%.

- Material Specifications: Standard construction represents the baseline. Stainless steel (304 grade) components add 20-30%, while corrosion-resistant (316 grade) materials increase prices by 40-60%.

Energy Efficiency Optimization Strategies

Reducing power consumption in dynamic batching systems involves multiple approaches that can significantly lower operational costs.

1. Motor and Drive System Optimization

- Variable Frequency Drives (VFDs): Install VFDs on all motor-driven components to match power consumption with actual operational requirements

- High-Efficiency Motors: Upgrade to IE3 or IE4 premium efficiency motors that typically reduce energy consumption by 3-8% compared to standard models

- Proper Motor Sizing: Ensure motors are correctly sized for their applications to avoid energy waste from over-sized equipment

2. System Design and Configuration

- Optimized Material Flow: Design material pathways to minimize conveying distances and reduce motor operation time

- Gravity Feeding: Utilize gravity-based feeding systems where possible to eliminate motor-driven conveying requirements

- Sequential Operation: Program systems to operate components only when needed, avoiding simultaneous operation of all motors

3. Control System Enhancements

- Smart Power Management: Implement control algorithms that optimize power usage based on production schedules and material characteristics

- Sleep Mode Configuration: Program systems to enter low-power modes during production pauses or scheduled breaks

- Efficient Start-Stop Sequences: Optimize startup and shutdown procedures to minimize energy-intensive peak power demands

4. Operational Best Practices

- Regular Maintenance: Keep all mechanical components properly lubricated and aligned to reduce friction and energy requirements

- Material Management: Maintain optimal material characteristics (moisture content, particle size) to minimize processing energy

- Production Scheduling: Batch similar products together to reduce changeover energy requirements and maintain consistent operation

5. Monitoring and Analysis

- Energy Monitoring Systems: Install power meters to track energy consumption patterns and identify optimization opportunities

- Performance Analytics: Use data analysis to identify inefficiencies and optimize system parameters for reduced energy usage

- Preventive Maintenance: Regular inspection and maintenance of electrical components to ensure optimal efficiency

Expected Energy Savings

Implementing these strategies can typically achieve:

- 15-25% reduction in overall energy consumption through motor optimization

- 10-20% savings from improved system design and control enhancements

- 5-15% additional savings through operational improvements and maintenance

- Total potential energy reduction: 30-60% depending on initial system configuration

Yuhang Technology Energy Efficiency Services

Yuhang offers comprehensive energy optimization solutions:

- Energy Audits: Detailed analysis of current power consumption patterns

- Efficiency Upgrades: Retrofitting existing systems with energy-saving components

- Control System Optimization: Programming enhancements for reduced power usage

- Maintenance Programs: Preventive maintenance services to maintain optimal efficiency

- Monitoring Solutions: Real-time energy consumption tracking and reporting

Return on Investment Considerations

Energy efficiency improvements typically offer:

- Payback periods of 12-24 months for most optimization measures

- Significant reduction in operational costs over system lifetime

- Improved system reliability and reduced maintenance requirements

- Enhanced environmental sustainability through reduced carbon footprint

Conclusion

While dynamic batching systems represent a significant capital investment, implementing proper energy efficiency measures can substantially reduce operational costs. The combination of technical improvements, operational optimizations, and regular maintenance can lead to dramatic reductions in power consumption while maintaining system performance and reliability.

Leave a Comment

Your email address will not be published. Required fields are marked *