Batching System Types and Costs: A Complete Overview

Are you researching the ideal automated batching system for your production line but feel overwhelmed by the options and pricing? Understanding the different batching system types and their associated costs is the crucial first step toward making a smart investment. At Yuhang Technology Co., Ltd., we specialize in engineering precision ingredient dispensing systems for a wide range of industries. This guide will break down the common types of systems and the key factors that influence their price.

What Are the Main Types of Batching Systems?

Batching systems are broadly categorized by how they measure ingredients. The two primary methods are gravimetric and volumetric, each with its own advantages and ideal applications.

1. Gravimetric Batching Systems

Gravimetric systems measure ingredients by weight, using highly accurate load cells. This is the preferred method for applications requiring extreme precision and recipe consistency.

- How it works: Ingredients are fed into a weigh hopper until the target weight is achieved.

- Best for: Industries where exact formula consistency is critical, such as food production, pharmaceuticals, plastics compounding, and specialty chemicals.

- Advantages: High accuracy, self-correcting (can adjust for material density variations), ideal for expensive raw materials.

2. Volumetric Batching Systems

Volumetric systems measure ingredients by volume, using mechanisms like screw feeders, vibratory trays, or pumps. The cost is often lower, but accuracy can be influenced by material density and flow characteristics.

- How it works: A predefined volume of each material is dispensed based on time and feeder speed.

- Best for: Applications where high throughput is more critical than ultra-high precision, or for handling free-flowing, consistent materials.

- Advantages: Lower initial investment, simpler design, faster for certain non-critical applications.

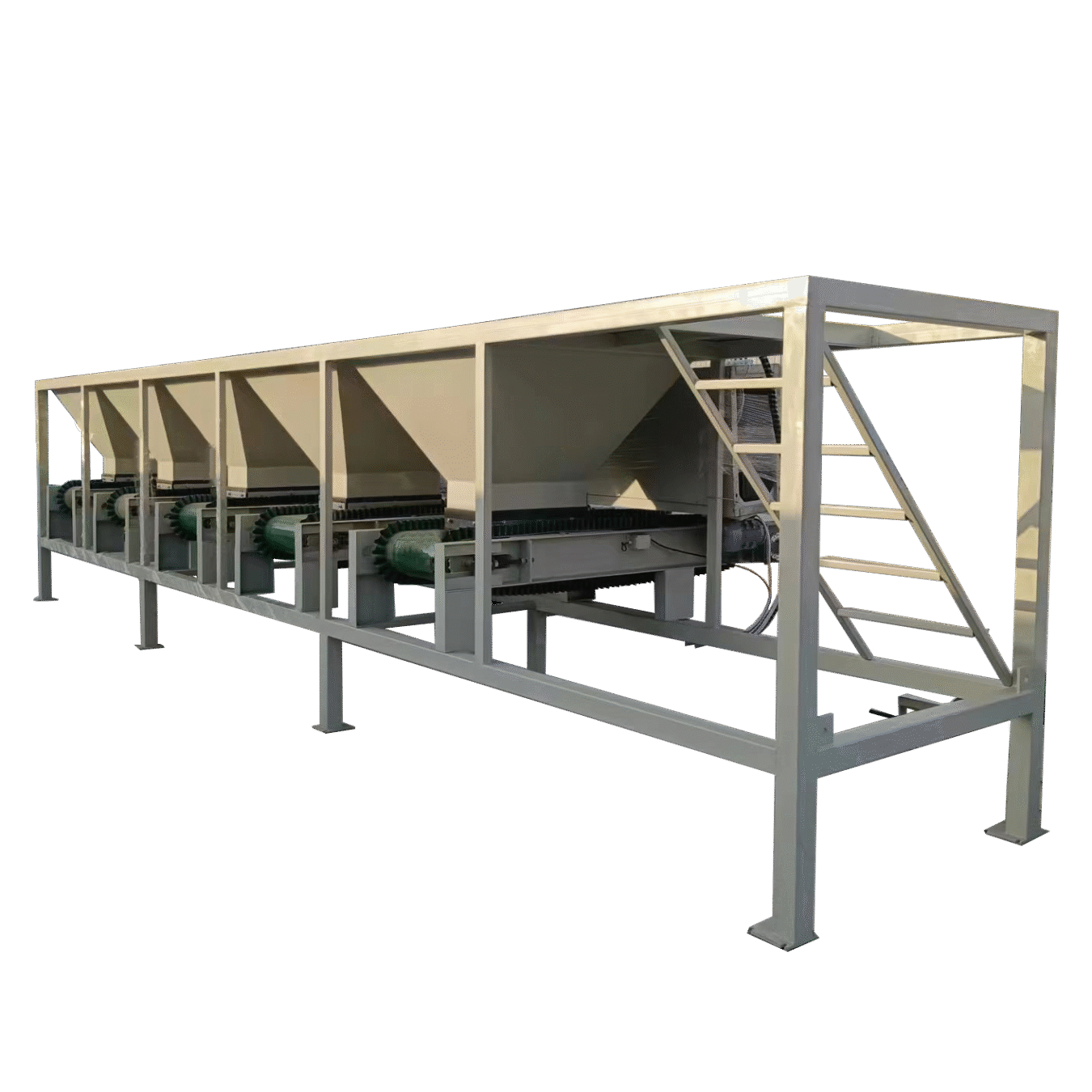

3. Hybrid and Multi-Ingredient Systems

Most modern industrial setups are hybrid or multi-component systems. A single line might use a gravimetric system for powders and a volumetric system (pumps) for liquids. Yuhang Technology excels at designing these custom batching solutions tailored to handle complex recipes with numerous ingredients efficiently.

How Much Does a Batching System Cost?

It’s challenging to state a single price for a batching system, as costs vary dramatically based on your specific needs. A small, simple system could start around $20,000, while large, fully automated, multi-station systems can easily exceed $200,000.

The final ingredient dispensing system price depends on several key factors:

Key Factors Influencing Cost:

- Level of Automation: A basic manual system is the least expensive. Costs rise with semi-automation and peak with fully automated, PLC-controlled systems with integrated ERP/MES software.

- Number of Ingredients: Systems designed to handle 5 ingredients will cost significantly less than those designed for 50 ingredients. More ingredients require more feeders, scales, and control complexity.

- Material Characteristics: The cost changes based on what you’re batching. Handling difficult powders (e.g., sticky, abrasive, or ultra-fine) or corrosive liquids requires specialized, often more expensive, components like stainless steel construction, special coatings, or specific feeder types.

- Accuracy Requirements: Achieving ±0.1% accuracy requires higher-end components (load cells, feeders, controllers) than a system rated for ±1.0% accuracy.

- Throughput (Capacity): Systems required to batch large volumes per hour require larger, more heavy-duty components, increasing the cost.

- Industry & Compliance: Systems for the food, pharmaceutical, or chemical industries often need certifications (e.g., USDA, FDA, ATEX) and specific hygienic designs (e.g., easy-clean surfaces), which add to the overall cost.

Why Choose Yuhang Technology for Your Batching System?

As a leading batching system manufacturer, Yuhang Technology doesn’t believe in one-size-fits-all solutions. We provide:

- Expert Consultation: We analyze your process, materials, and goals to recommend the most efficient and cost-effective batching system type for you.

- Precision Engineering: Our weighing and batching systems are built for reliability and unparalleled accuracy, ensuring product quality and reducing material waste.

- Custom Solutions: Whether you need a powder batching system, liquid batching system, or a complex hybrid, we desi

Leave a Comment

Your email address will not be published. Required fields are marked *