The dynamic batching system, usually referred to as the “Loss-in-Weight Feeding System”, is a cutting-edge solution in modern industry for achieving high-speed, continuous, and high-precision multi-group batch ratios. Its core principle lies in “real-time monitoring of the rate of weight loss and dynamic adjustment of the feed”, rather than static weighing. Let’s delve deeper into its working principle:

Core working principle: Continuous weightlessness + Flow control

System Initialization and Pre-Filling:

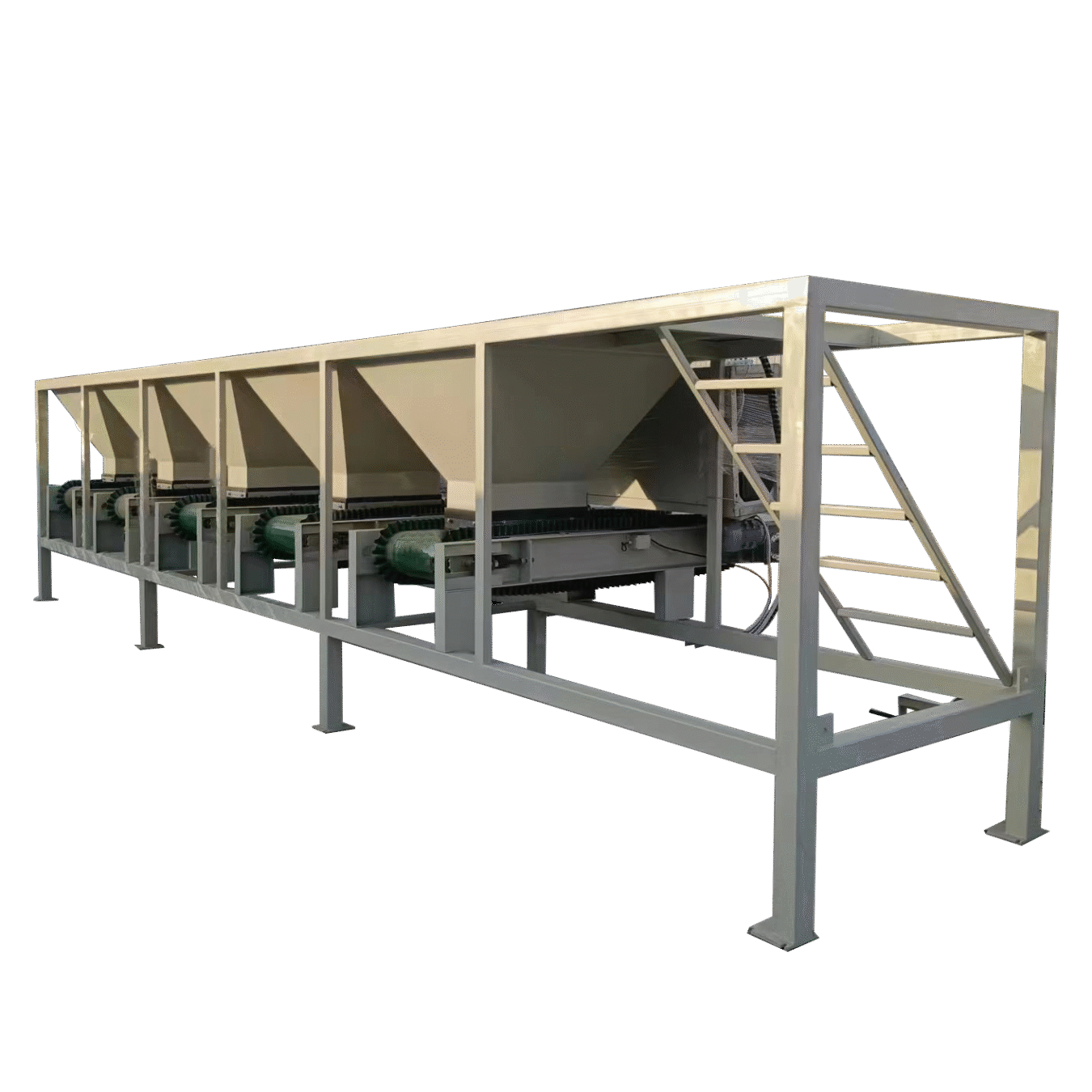

- Each material that requires precise proportioning has an independent subsystem, which includes:

- Storage Bin: Stores a large quantity of materials.

- Weighing Hopper (Weight Loss Hopper): Located below the storage bin, equipped with high-precision weighing sensors.

- Feeding Equipment: Installed at the bottom outlet of the weight loss hopper, such as single/double screw feeders, vibrating feeders, belt scales, etc. Their speeds can be precisely controlled.

- Before the system is started, the weight loss hopper will be filled to the set higher weight level (such as 60-80% of the hopper capacity).

- Start the ingredient setting and flow rate configuration:

- The operator sets the recipe in the production control system, specifying the target mass flow rate (e.g., kg/h) or ratio for each material.

- Start the continuous ingredient dispensing process.

- Key Point: Real-time Gravity Measurement and Closed-loop Control:

- This is the essence that distinguishes the dynamic batching system from the static system. **

- All the feeding equipment for the materials start running simultaneously, and the materials flow out from their respective weightless hoppers and enter the downstream mixer or total conveyor line.

- High-precision weighing sensors continuously and real-time monitor the weight changes of each weightless hopper. The core of the system’s calculation is not “What is the current weight?”, but “What is the rate of weight decrease?”.

- Control core (PID algorithm): The control system compares the actual weight loss rate (i.e., the actual flow) measured in real time with the target flow set in the recipe.

- If the actual flow < target flow: The system will increase the rotational speed (or amplitude, speed, etc.) of the feeding equipment to accelerate the material outflow.

- If the actual flow > target flow: The system will reduce the rotational speed (or amplitude, speed, etc.) of the feeding equipment to slow down the material outflow.

- This measurement->comparison->adjustment process is a high-speed, continuous, closed-loop feedback control loop, usually completed within milliseconds, ensuring that the actual flow closely follows the target flow.

- Material replenishment stage:

- As the materials continue to flow out, the weight of the weightless bin will keep decreasing.

- When the weight of the weightless bin drops to the preset low level, the system needs to replenish the materials.

- Switch to volume mode (temporary): At this point, the control system will temporarily shut off the precise flow control loop for this material. The replenishment valve above the storage bin (such as an air-operated butterfly valve or gate valve) opens, and the materials flow rapidly into the weightless bin for replenishment.

- Key point: During the replenishment period, since the weighing sensor cannot accurately measure the flow rate of the weightless bin (because the weight is increasing), the system will briefly estimate and maintain the material flow rate based on the stable feeding equipment speed (or opening degree) before replenishment (i.e., “volume control”). The accuracy will slightly decrease during this stage.

- Return to weightless mode: When the weight of the weightless bin is replenished to the preset high level, the replenishment valve closes. After the weight is detected to be stable, the system immediately reactivates the precise weightless closed-loop control. The replenishment process should be as fast as possible to minimize the impact on overall accuracy.

- Multi-component Synchronization and Mixing:

- Each subsystem of the individual materials is independently conducting the aforementioned weightlessness control and feeding cycle.

- Since each material is strictly output according to its target flow rate, and these target flow rates are set based on the mixing ratio, multiple materials naturally maintain an accurate proportionate relationship when entering the downstream mixing points (such as the inlet of the mixer, the total conveyor belt), achieving continuous and uniform mixing as the foundation.

Summary of Core Features - Independent Gravity Feeding: Each material has a dedicated weighing hopper and control system.

- Continuous/Quasi-Continuous Output: The materials are continuously or nearly continuously output in proportion, rather than in batches.

- Dynamic Control: High-speed closed-loop regulation is performed based on the real-time weight loss rate (flow rate).

- Synchronous Mixing: Multiple materials are output simultaneously in proportion to achieve continuous mixing.

- High Precision Guarantee (especially for trace amounts): The weight loss principle provides extremely high accuracy for trace addition and proportional control (typically ±0.1% – ±0.5% or even better), unaffected by fluctuations in material density (measured is the mass flow rate).

- Feed Strategy: The “gravity control as the main approach + short-term volume control for feeding” mode is adopted to maintain continuous operation.

Implementation of the supporting principle for key components - Weightlessness斗 and weighing unit: The core measurement unit, requiring high sensitivity, high stability, and strong anti-interference capability.

- Precise feeding equipment: The key execution unit, must have good controllability, linearity, and repeatability (such as servo motor-driven screw, high-performance vibrating feeder).

- High-speed controller and advanced algorithms (PID and optimization): The brain. Real-time data processing, high-speed closed-loop control, material replenishment logic switching, anti-interference (such as vibration).

- Storage bin and replenishment device: To ensure the material supply for the weightlessness斗, replenishment should be fast and with minimal disturbance.

- Downstream mixing/suction equipment: Receives the proportionally input material flow for continuous mixing.

Advantages and Applicable Scenarios

- Advantages:

- High precision: Particularly adept at handling trace components (<1%) and strict ratio requirements.

- Continuous production: Reduces batch intervals, enhances efficiency, and is suitable for large-scale production.

- Flexible formula switching: Can quickly switch to different formulas through the control system.

- Handling multiple components: Easily cope with the precise mixing of dozens or even hundreds of materials.

- Reducing batch variations: Continuous output is more stable.

- Applicable scenarios:

- Complex and variable formulas, with a wide variety of materials.

- Requires continuous or large-scale production.

- Has extremely high precision requirements, especially for trace additives.

- Material characteristics may have certain fluctuations (mass measurement by weight method, insensitive to density changes).

- Common industries: High-end plastic extrusion and granulation (color masterbatches, additives), food industry (fragrances, vitamins, trace elements), pharmaceuticals (active ingredients, excipients), fine chemicals (catalysts, additives), lithium battery electrode pastes, special building material additives, etc.

Dynamic Ingredients vs. Static Ingredients: The Core Difference

Feature Dynamic Feeding System (Weightless) Static Feeding System

Working Principle Real-time monitoring of weight loss rate, dynamic adjustment of feeding Sequential static weighing, accumulated to a single bucket

Output Mode Continuous/Quasi-Continuous Proportional output Batch-style Full batch discharge

Weighing Core Mass Flow Rate (Weight Loss Rate) Cumulative Weight

Control Method High-speed Closed-loop Feedback (PID, etc.) Sequential Open-loop Control (Coarse/Finer Feeding)

Structure Multiple Ducts Parallel (Each material independent subsystem) Single Duct Concentrated

Precision Advantage Micro addition, proportional control Extremely high precision Single material static weighing High precision

Speed Advantage Continuous High-speed Relatively slow (Requires sequential waiting)

Applicable Scale Large-scale continuous production Medium and small-scale batch production Summary The core principle of the dynamic batching system (weightless type) lies in “Independent weightlessness, real-time flow measurement, closed-loop speed regulation, synchronous constant flow“. It continuously monitors the weight loss rate of each material hopper and precisely adjusts the speed of the feeding equipment using a high-speed closed-loop control algorithm to ensure that each material is output at the set quality flow rate stably. This constant and proportional output flow of multiple materials converges at the mixing point, laying the foundation for continuous, uniform, and high-precision mixing. This “weightless” dynamic control principle enables it to demonstrate unparalleled advantages in complex formulations, continuous production, especially in scenarios requiring traceable high-precision ratios, and thus becomes a key technical pillar in modern process industries and precision manufacturing.

Leave a Comment

Your email address will not be published. Required fields are marked *