In the field of industrial material dispensing, the static dispensing system has become the preferred solution for many industries due to its reliable structure, high precision (especially for specific materials), and relatively low cost. The core of this system lies in “static weighing” and “sequential addition”. The following is a detailed explanation of its working principle:

Core working principle: Sequential weighing + Central hopper

- Recipe Setup and Start-Up:

- The operator inputs or selects the desired production recipe in the production control system (such as PLC, DCS, or dedicated batching controller). The recipe specifies the name of each material and the target addition weight or ratio.

- Start the batching batch.

- Material Addition Sequence:

- This is the most distinctive feature of the static batching system. The system strictly follows the sequence set by the recipe, one by one, adding various materials to the same central weighing hopper.

- Feed Control:

- The system activates the feeding equipment (such as gravity gates, spiral feeders, vibrating feeders, belt feeders, etc.) below the storage bin of the first material.

- The material begins to flow into the central weighing hopper.

- High-precision weighing sensors continuously monitor the weight changes in the central hopper.

- Precise Weighing Process:

- Coarse Feeding Stage: The feeding equipment typically adds material to the hopper at a relatively fast rate (high flow rate), rapidly approaching the target weight.

- Fine Feeding Stage: When the weight of the material in the hopper approaches the target value (such as reaching 90-95% of the target value), the system controls the feeding equipment to switch to a slow (low flow rate) or point-motion mode. This is similar to “slowly and steadily” pouring water, avoiding overfilling.

- Achieving the Target: When the sensor detects that the weight of the hopper has precisely reached the target set value for this type of material, the system immediately shuts off the feeding equipment for this material and stops adding.

- Next material addition:

- After the first material is added, the system automatically switches to the next material according to the recipe sequence.

- Repeat steps 2 and 3: Open the feeding equipment of the corresponding silo, perform coarse feeding -> fine feeding -> reach the target -> stop.

- This process is carried out in sequence, until all the materials in the recipe have been added to the central hopper according to the set quantity. Each material is independently weighed while the hopper is stationary. **

- Batch Completion and Discharge:

- Once all the materials have been added, a complete “batch” is formed in the central weighing hopper (at this point, the materials have not yet been mixed or only preliminarily mixed).

- The system opens the discharge valve at the bottom of the central hopper (such as an air-operated butterfly valve, gate valve, etc.).

- The entire batch of materials is discharged by gravity (or supplemented by vibration, fluidization devices to prevent clogging) and transported to the downstream equipment, usually to a mixer for uniform mixing, or directly entering the next process (such as packaging, reaction vessel, etc.).

- Reset and Next Batch:

- Discharge is complete, and the discharge valve is closed.

- The system is reset, and preparations are made for the next batch of ingredient addition. The new batch is added sequentially starting from the first type of material.

Summary of Core Features - Single-bin weighing: All materials share a single central weighing bin.

- Sequential execution: Materials are added and weighed in accordance with the recipe in a sequential manner.

- Static weighing: Each material is precisely weighed in the static state of the bin (stable reading after the feeding stops).

- Batch operation: After all materials are added to form a batch, the entire batch is discharged.

- High precision guarantee: Independent precise feeding stage and static weighing mode ensure that each material (especially those with good fluidity and not prone to sticking) can achieve very high weighing accuracy (typically ±0.1% – ±0.5% or higher).

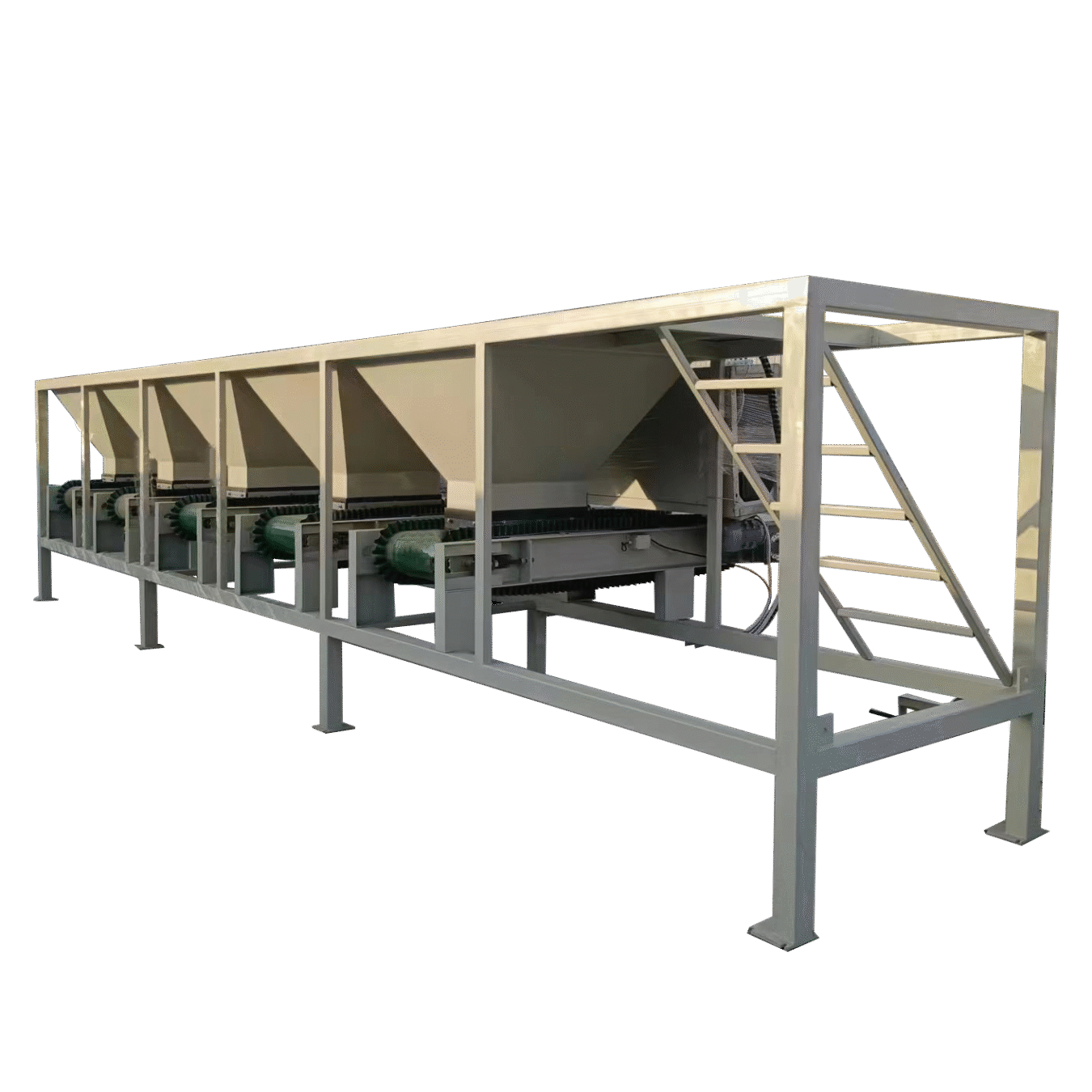

Implementation of the supporting principle for key components - Central weighing hopper: The core container, equipped with high-precision weighing sensors (such as strain gauge type, electromagnetic force compensated type) and controllers.

- Storage bins and feeding equipment: Each material storage bin is equipped with a controllable feeding mechanism to achieve coarse/fine feeding control.

- Discharge valve: Reliable control of the discharge of batch materials.

- Control system (PLC/DCS/dedicated controller): The brain. It executes formula management, sequence control, feeding logic (coarse/fine), weight comparison, equipment start/stop, data recording, alarms, etc.

- Dust removal system (optional but important): Controls dust during feeding and discharging processes.

Advantages and Applicable Scenarios

- Advantages: The structure is relatively simple and easy to maintain; single-point weighing, high and stable accuracy (for suitable materials); good cost-effectiveness; easy to clean (especially for industries with high hygiene requirements such as food and pharmaceuticals).

- Application scenarios:

- Material types are moderate (such as 5-20 types).

- Formulas are relatively fixed or do not change extremely frequently.

- Batch-based production mode.

- Materials have good fluidity, and are not prone to severe sticking or bridging in the hopper.

- High precision requirements (especially for main materials and materials with good fluidity).

- Common industries: food processing (flour, sugar, milk powder, etc.), plastic granulation, some chemical raw materials, building material premixes, feed premixes, etc.

Summary

The core principle of the static batching system lies in “Sequential addition, static weighing, single-bucket accumulation, batch discharge“. It precisely controls the process of each material being added to the central hopper in sequence, and completes high-precision weighing in a static state, ultimately forming a complete batch of raw materials. This principle determines that it is particularly suitable for batch production processes with stable formulas, high precision requirements, and good material adaptability. It is an indispensable classic solution in the field of industrial batching.

Leave a Comment

Your email address will not be published. Required fields are marked *