Types of Batching Systems: Key Differences Explained | Yuhang Tech

Understanding the Key Differences Between Types of Batching Systems

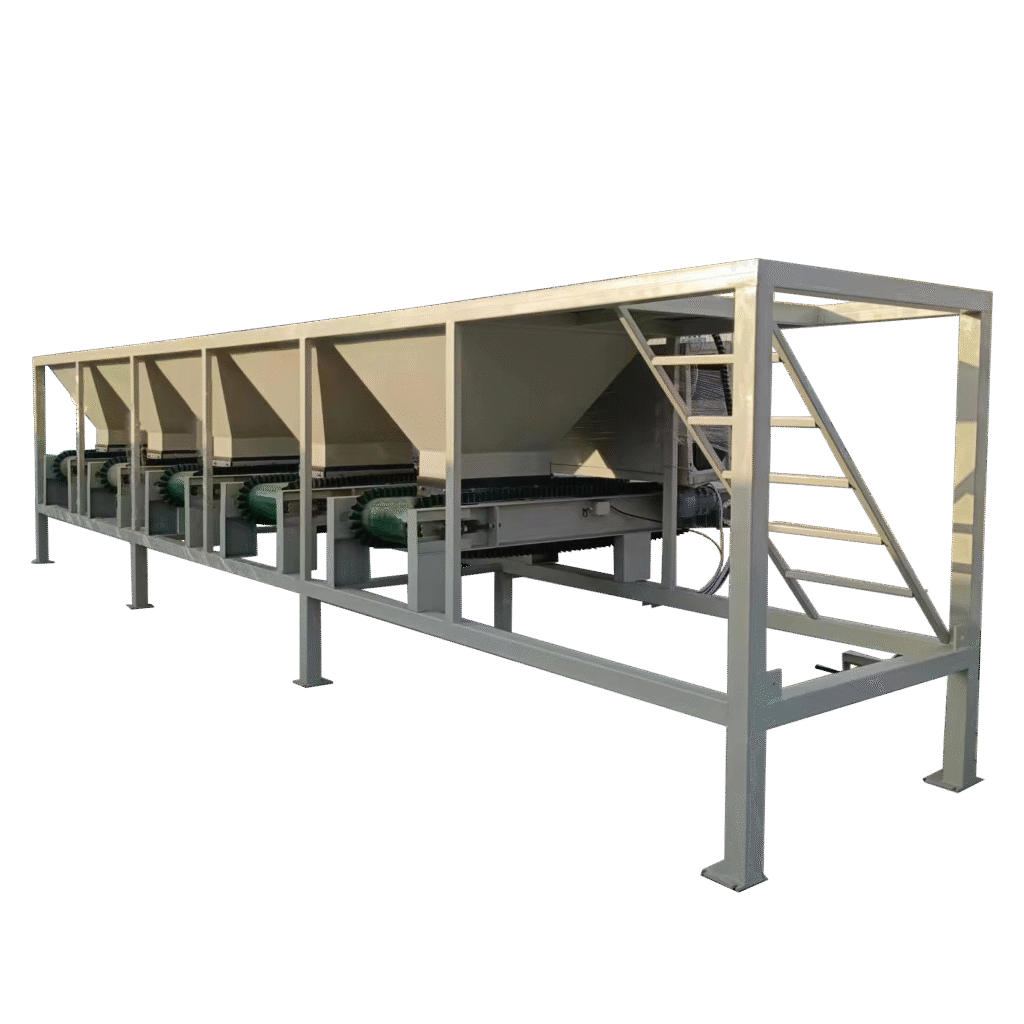

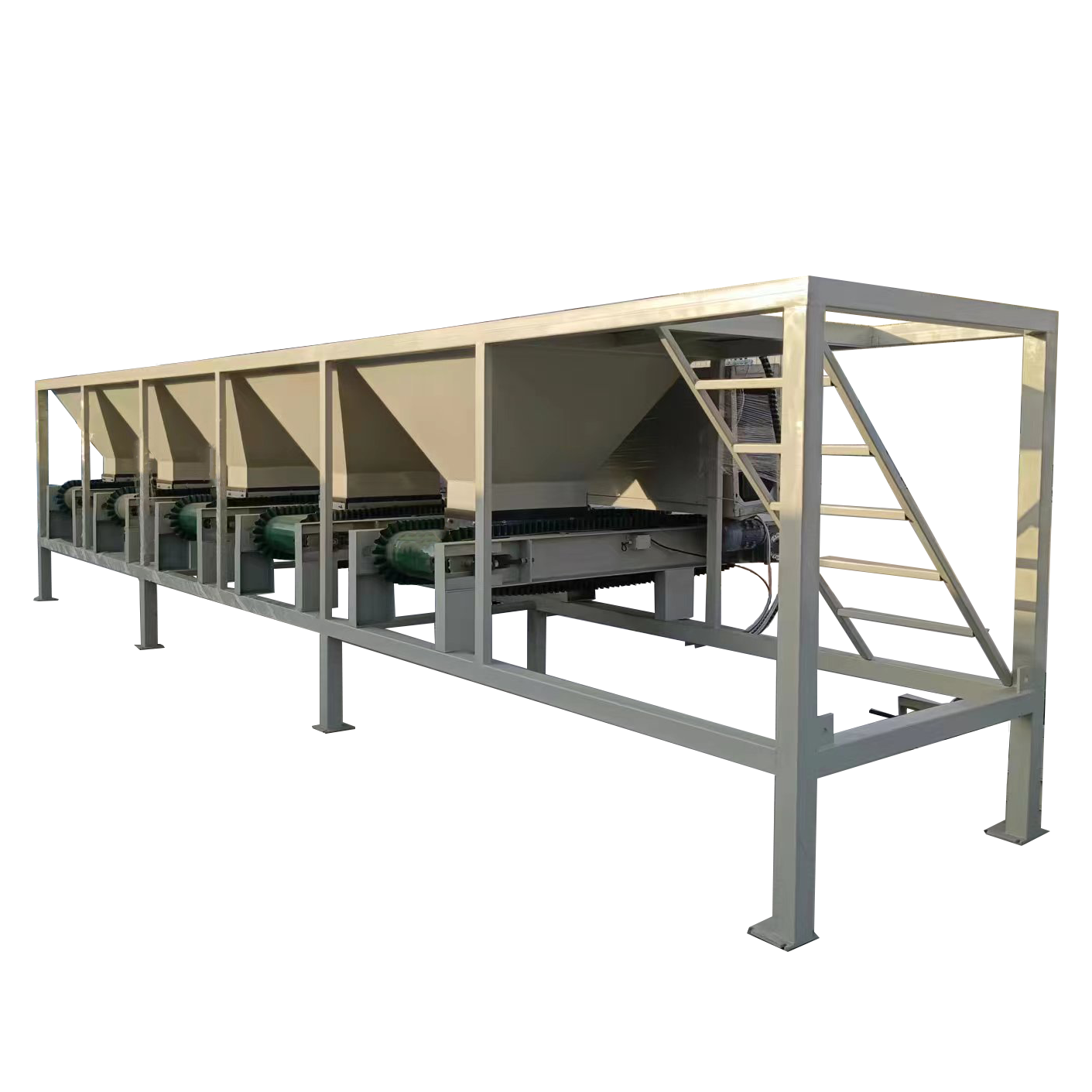

Selecting the right batching system is crucial for manufacturing efficiency and product quality. While all batching systems serve the same fundamental purpose – accurately combining multiple ingredients – their methods, capabilities, and ideal applications vary significantly. At Yuhang Technology Co., Ltd., we help manufacturers navigate these differences to find the perfect solution for their specific needs. This article breaks down the key distinctions between the main types of ingredient dispensing systems.

Core Differences in Measurement Methodology

The most fundamental difference between batching systems lies in how they measure materials, which directly impacts their accuracy, cost, and suitability for various industries.

Gravimetric vs. Volumetric Systems

Gravimetric Batching Systems measure ingredients by weight using precision load cells. This method provides exceptional accuracy, typically within ±0.1% to ±0.5%, by directly measuring mass rather than volume.

Volumetric Batching Systems measure ingredients by volume using mechanisms like screws, vibratory feeders, or pumps. These systems dispense a predetermined volume of material based on time and feeder speed, making them generally less accurate than gravimetric systems but often more cost-effective.

Key Operational Differences

- Accuracy: Gravimetric systems maintain consistent accuracy regardless of material density changes, while volumetric systems can be affected by variations in material density, humidity, and flow characteristics.

- Self-Correction: Gravimetric systems automatically compensate for variations in material density, while volumetric systems require manual calibration for different materials.

- Material Handling: Volumetric systems often handle free-flowing materials more efficiently, while gravimetric systems excel with materials that have inconsistent density or flow properties.

Specialized System Variations and Their Unique Features

Beyond the basic measurement distinction, batching systems differ significantly in their design and specialization for specific industries and materials.

Powder vs. Liquid Batching Systems

Powder Batching Systems typically use screw feeders, vibratory trays, or weigh hoppers. They require specific designs to prevent bridging, rat-holing, and dust generation. These systems often feature specialized seals and surface finishes to handle fine particulates.

Liquid Batching Systems utilize pumps, flow meters, and valves for accurate dispensing. They require different considerations for viscosity, temperature control, and cleaning (CIP – Clean-in-Place systems). These systems often feature tanks, heaters, and pressure-rated components not found in powder systems.

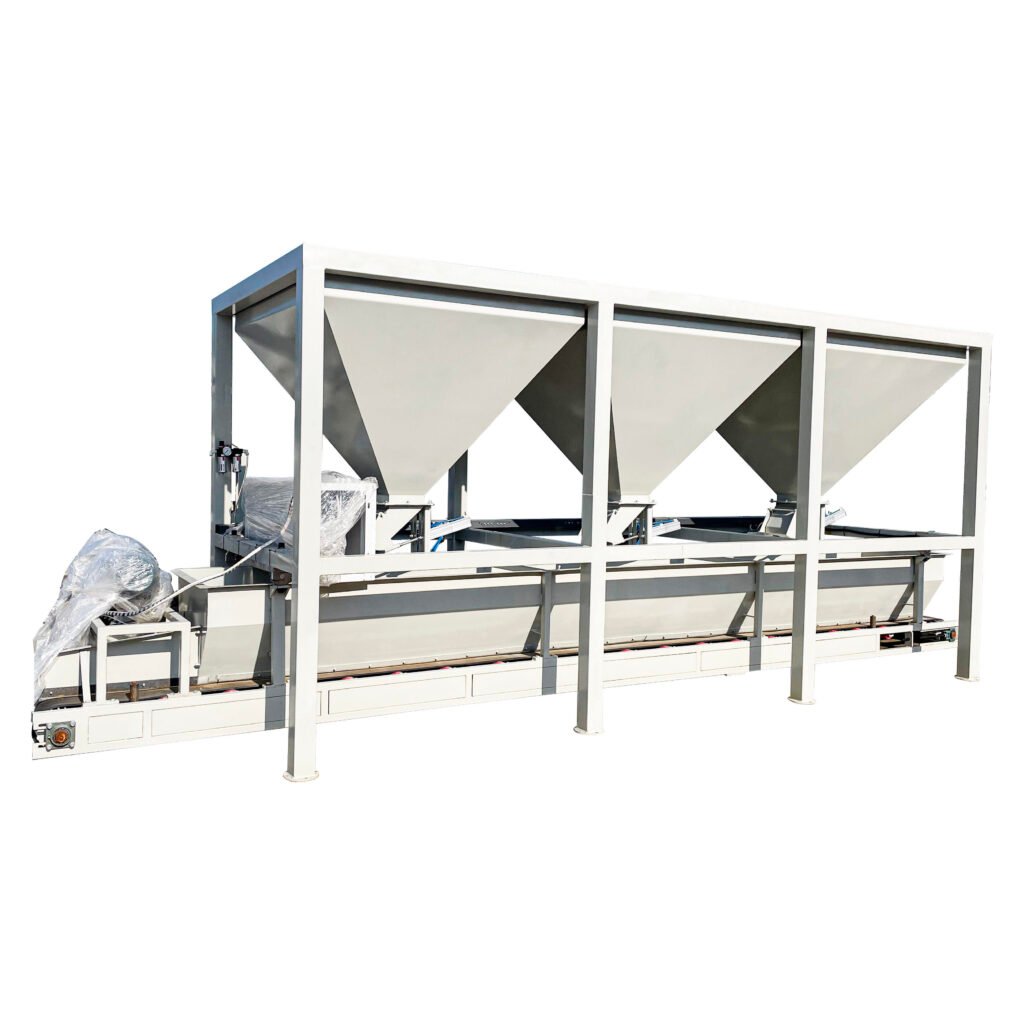

Single-Ingredient vs. Multi-Ingredient Systems

The complexity increases substantially with the number of ingredients handled. Single-ingredient systems focus on high-volume dispensing of one material, while multi-ingredient systems require sophisticated sequencing, cross-contamination prevention, and recipe management capabilities.

Industry-Specific System Variations

Different manufacturing sectors have unique requirements that significantly influence batching system design and functionality.

Food & Pharmaceutical Grade Systems

These systems prioritize hygienic design with stainless steel construction, easy-clean surfaces, and compliance with industry regulations (FDA, USDA, GMP). They often feature specialized coatings and validation documentation not required in industrial applications.

Industrial & Chemical Systems

Designed for harsh environments, these systems emphasize durability, corrosion resistance, and explosion-proof components (ATEX certification). They typically handle abrasive or hazardous materials requiring specific material contact surfaces.

Automation Level Differences

Batching systems vary widely in their level of automation and control sophistication:

- Manual Systems: Operator-dependent with basic controls

- Semi-Automated Systems: Partial automation with recipe storage

- Fully Automated Systems: Complete integration with ERP/MES systems, remote monitoring, and predictive maintenance capabilities

Choosing the Right System: Key Considerations

Understanding these differences helps manufacturers select the appropriate system based on:

- Accuracy Requirements: Gravimetric for precision, volumetric for general accuracy

- Material Characteristics: Free-flowing vs. difficult-to-handle materials

- Industry Standards: Hygienic requirements vs. industrial durability

- Production Volume: High-speed vs. batch processing needs

- Future Flexibility: Scalability and recipe change frequency

At Yuhang Technology, we specialize in designing custom batching solutions that address these differences while optimizing for your specific manufacturing requirements. Our expertise ensures you get a system that not only handles your materials accurately but also integrates seamlessly with your production processes.

Need Help Determining Which System is Right for You?

Contact Yuhang Technology today for a professional assessment of your batching needs and a customized solution that addresses your specific operational requirements and challenges.